- Home

- Companies

- GreenPower

- Products

GreenPower products

Pyrolysis Furnaces

GreenPower BIO-KILN - Continuous Carbonization Furnace

The carbonization furnace BIO-KILN is a patented, environmentally friendly, continuous installation for the thermal processing of plants materials. It is designed specifically for the production of high-quality charcoal or biochar as a raw material for the production of hookah charcoal, BBQ briquettes, activated carbon. The charcoal-burning complex based on the BIO-KILN carbonization furnace allows automating the entire production process of producing charcoal: the processes of loading raw materials and unloading finished charcoal, it also makes it possible to automatically control the content carbon in charcoal, minimize ash content, increase the output of charcoal, eliminate the influence of the human factor and achieve consistently high performance indicators of the furnace.

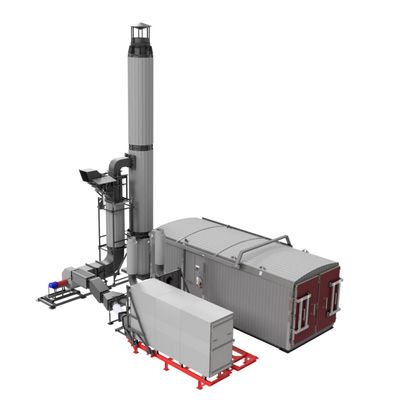

GreenPower EKKO - Charcoal Furnace

Environmentally friendly furnace for carbonization of raw materials, including: energy and plantation wood and wood waste, fuel-briquettes (Pini-kay, nestro, ruv, etc.) and plantation wastes to produce high-grade charcoal. The main process used in the furnace is carbonization or low speed pyrolysis of plant materials containing carbon. In addition to the production of charcoal, heat energy is generated in the process. Extra heat can be used for preliminary drying of the raw material or for other purposes. If the customer wishes, it is possible to produce liquid pyrolysis products. Charcoal is widely used in almost all spheres of the global economy (see more details on the use of charcoal). Production of environmentally friendly high quality charcoal is an urgent problem in the development of the world economy.

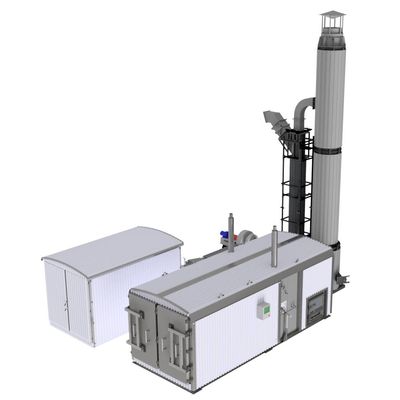

GreenPower Carbon-Flow - Continuous Lump Charcoal Production Furnace

Carbon-Flow system represents the forefront of lump charcoal production eco friendly technology, designed with a focus on efficiency and sustainability. Developed with insights from Perechenskiy LHK in Perechin, Ukraine, this system minimizes human involvement and maximizes the use of internal heat for the pyrolysis process, ensuring a high-output and low-energy operation. The unit is designed for continuous production of high-quality lump charcoal from wood logs and wood waste.

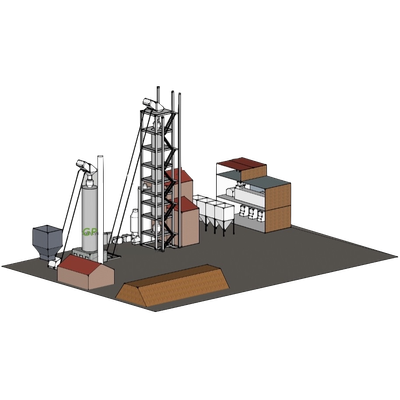

GreenPower - Logistics Elements For Carbonization Furnace

Logistics elements allow you to optimize the production process and reduce production costs. Avoiding manual labor is a key requirement for responsible equipment management for safety.

Drying Equipment

GreenPower BIO-KILN - Excess Heat Recovery Unit for the Carbonization Furnace

Excess heat recovery unit from BIO-KILN is designed to produce thermal energy in the form of: flue gases, hot water, hot air and other heat carriers. Excess heat recovery unit is made of heat resistant steel. The basic set of delivery provides for the removal of excess heat during the operation of the carbonization furnace BIO-KILN, which have high temperatures of 1000-1200°C and lowering their temperature to the required from 60 to 300°C. Excellent drying heat balance achieved by adjustable cold air ducts, that is, lowering the temperature of flue gases is achieved by diluting them with cold air. Excess heat recovery provides a system for automatic control of the temperature of the heat carrier within the specified temperature (60-300°?).

GreenPower EKKO - Preliminary Dryer for the Carbonization Furnaces

Pre-drying (PD) is a device for automatic preparation of a heat carrier – a drying agent for use in drying devices. The basis of the heat carrier is the excess heat released during the pyrolysis process. Preliminary dryer is used to “quickly and efficiently” remove moisture from wood to obtain dry raw materials for pyrolysis. Preliminary drying takes place outside of the drying/pyrolysis chamber, which can significantly shorten the cycle time and increase the productivity of the kiln from 50 to 100% when using “fresh” wood.

GreenPower - Pre-drying Chamber for Carbonization Furnace

The Pre-drying chamber is very necessary in cold times of the year, also if charcoal produces open air. This chamber needs of course the preliminary drying system (see description), because it’s using the extra heat of the pyrolysis reaction. The main task of the pre-drying chamber is to minimize heat loss during the drying of wood directly in the trolley. The charcoal furnace EKKO (see description) is equipped with an automatic preliminary drying temperature control system, which can vary between 100-200°C. The production cycle is 10-16 hours, same as in the chamber of a carbonization furnace, depending on the parameters of the woods used for drying. The pre-dryer chamber uses the trolleys of the carbonization furnace EKKO (see description). The pre-drying chamber is sent to the consumer in disassembled form, to minimize logistic costs.