Haat Incinerators India Pvt Ltd. products

Haat - Model ADR - Incinerator

The Haat ADR range of incinerators is fairly large, from 10 kg/h to 1000 kg/h. It is designed primarily for the disposal of animal waste and biomedical waste, but can handle with ease other wastes such as general garbage, pharma waste, certain hazardous wastes, etc.

Model SRD - Skid Mounted Incinerator Package

Engineered for customized needs. Suitable for oil drilling and camp sites on-site incineration. Easy to transport, install and operate. Engineered for customised needs: Skid mounted incinerator package designs are preferred where the operations shift from one place to the other or when maximum shop fabrication is preferred and minimum site services are required. These incinerator packages are supplied with all equipment on skid with complete cable, instrumentation, piping, etc. readymade and ready to operate.

Haat - Model PDR - Incinerator

Haat model PDR is a versatile incinerator that can be used for most waste applications. It is of a cylindrical, modular design, which enables no `cold spots` in the combustion chamber and makes it easy to add more modules, should the need arise, to increase the capacity of the primary combustion chamber. In the case of the secondary chamber, as regulations may require an increase in the residence time from 0.5 seconds to 2 seconds (depending on statutory rules for different countries), it has a provision to increase it further without having to purchase a new incinerator.

Haat - Model SWR - Marine / Shipboard Incinerator

The introduction of the SWR model incinerator to Haat`s range of products has not only fulfilled the need for a product of this type, but has also served as an answer to the call given by the Government of India to `Make in India` with regard to incinerators. Such a Marine Incinerator system has not been available indigenously. This has bridged the gap for an Indian incinerator for use by cruise ships, Navy and coast guards, cargo vessels, tanks, offshore platforms, shore based disposal facilities as well as furnace oil fired power plants. The applications exist not only within India but everywhere in the world. The SWR model Marine Incinerator is probably the only Indian incinerator to be type approved and certified for MED B + D by DNV-GL Norway. It conforms to the requirements of IMO and has a wide range from 200 to 2400 kW.

Haat - Model TDR - Containerised Incinerator

Haat`s range of incinerators include stand-alone units, skid mounted units as well as containerized units. Skid mounted and containerized units are invariably chosen where capacity of the equipment is not very high. The containerized model TDR is chosen primarily to enable movement of the incinerator from one place to another and these units can be connected either to a mobile generator or AC supply at site. Containerized units enable location of the incinerator, fuel tank, control panel, etc. in one container (subject to size) making it easy to move and operate. The TDR model can also be supplied with air pollution control equipment like dust collectors, scrubbers, etc.

Haat - Model PMR - Incinerator

Haat Model PMR Incinerator for Precious Metal Recovery. Reuse, recycle and recover have now become key phrases in industry as well as all walks of life. Waste oil is recycled, recovering a good percentage, precious metal is recovered from e-wastes and food waste and other organic wastes are composted and reused as fertilizer. Precious metal is also recovered from other sources such as jewellery manufacture and pharmaceutical processes. Haat has in its range a Precious Metal Recovery Incinerator, model PMR, which has now become popular in the jewellery and pharma industry, where there is plenty of scope to recover the yellow and white metals.

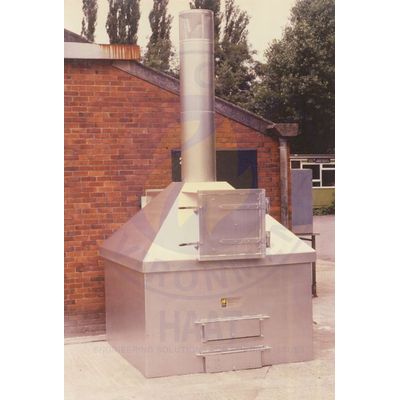

Haat - Model LD/MD /HD - Incinerator Trash Destructors

Haat has a unique range of Trash Destructors or single chamber incinerators. These are "Free Burning", meaning no fuel is used in burning the waste. This exclusive feature makes it one of the most sought after products because it has practically no running cost.

Haat - Model PWR - Incinerator

The PWR model has been installed in several farms particularly for chicken or other birds, broilers, hatcheries as well as to slaughter houses and meat processing centres for offal. The design considers for example, the high moisture content in eggs, air flow for complete incineration with minimum fuel usage.