10 products found

Henan Doing Mechanical Equipment Co., Ltd products

DOING - Model DY-C - Free installation 100/500kg/d plastic scrap to fuel oil pyrolysis plant

This is the 2022 new design 100/500kg/d frame type plastic/tyre scrap to fuel oil pyrolysis plant. It is installed in the frame type before shipping to customers, so it is has the advantages of easy-handling in the epidemic time. And you can put the pyrolysis plant into operation fastly once you receive it.

Advantages: Easy handling, free installation, mobile, small footprint, which can meet the needs of home, experiment and trial test uses.

Welcome to contact us to get the free quote if interested.

http://www.wastetireoil.com

Whatsapp/Tel: +86 13526692320

E-mail: oilmachine@wastetireoil.com

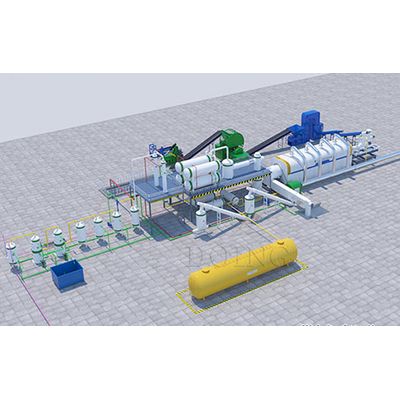

DOING - 100% Factory price customize15-50TPD Fully Continuous Pyrolysis Plant

DOING fully continuous pyrolysis plant is used to recycle waste solids into fuel, carbon black, and combustible gases at high temperatures.

Advantages: continuous working for 24 hours, high profits, high efficiency, higher safety&environmental degree, EU emission standard

Applications: Waste rubber tires/plastics/rubber powder/oil sludge, etc.

Projects: Kazakhstan, Brazil, Spain, Russia, Chongqing, Yunnan, etc.

As a leading manufacturer, we have exported and installed pyrolysis plants in 90+ countries and regions. Our high quality pyrolysis plants are highly recognized by customers.

DOING provides permanent after-sales service for users, including but not limited to 1-year quality warranty, instruct to get market for final products, online or onspot guidance related to technology, plant planning, equipment upgrading, etc. Consult us for best support and free quotations.

Whatsapp/Tel: +86 13526692320

E-mail: oilmachine@wastetireoil.com

Offcial site: http://continuouspyrolysisplant.com

DOING - Model 1-50TPD - Pyrolysis Plant

DOING pyrolysis plant for sale is a machine that is used to dispose of plastic, waste tire/rubber, and oil sludge. With a pyrolysis machine, you can get useful and valuable end products: pyrolysis oil, carbon black, and combustible gas. Pyrolysis oil can be used as fuel instead of coal. Meanwhile, pyrolysis equipment can reduce the pollution of used tires, plastics, oil sludge.

It plays an important role in establishing an eco-friendly world. Therefore, a pyrolysis plant is popular in most countries. Investors would get a high ROI from pyrolysis projects. Welcome to contact DOING to get the integrated solutions for your projects!

Because of capacities and particular configurations, DOING pyrolysis machinery can be classified as mobile skid-mounted, batch, semi-continuous, and continuous machines. Here, we would like to share more information about each type of machine.

DOING - Model 1-50 - Pyrolysis Plant in China From Leading Manufacturer-Henan DOING Group

DOING Pyrolysis plant in China is a specialized facility designed to process various types of waste into valuable products, including pyrolysis oil. Henan DOING Group is a highly reputable manufacturer and supplier of pyrolysis plants in China, renowned for providing flexible solutions and a range of comprehensive after-sales services. If you are interested in pyrolysis technology, please feel free to contact us.

At DOING, we offer a variety of waste pyrolysis solutions tailored to meet specific requirements. Our team can customize solutions based on the composition of the raw materials provided by customers and the intended applications of the final products.

DOING Company - Model DY - Green Technology 5-50TPD Solid Waste to Energy Machine Convert Tire Plastic to diesel Plant

Henan DOING Environmental Protection Technology Co.,Ltd, the subsidiary company of DOING Holdings Co.,LTD, is a comprehensive environmental equipment manufacturer integrating technological design, research and development, machine production, sales and after-sales service in one.

Relying on excellent technical R&D strength and innovative spirit, our company has won up to 23 new utility patents and invention patents. And our company is honored as the National High Technology Enterprise awarded by the Municipal Science and Technology Commission.

Our main business: solid waste and hazardous waste treatment equipment, waste tire/plastic/oil sludge/rubber/aluminum plastic

pyrolysis plant, pyrolysis oil/used oil to diesel distillation plant, and related environmental protection devices.Continuous waste tire pyrolysis machine with no secondary pollution

DOING - Model 20TPD/30TPD/50TPD/80TPD/100TPD - Fully continuous waste tire to fuel oil plant with advanced pyrolysis technology

Fully continuous waste tire to fuel oil pyrolysis plant can convert waste tire/tyre into fuel oil, carbon black, steel wire as the end product. It is feasible in technology and with bright future.

The main feature of Doing fully continuous waste tire to fuel oil pyrolysis plant are:

1. Feeding in every second and minute,automatic ejiecting wastes residue,Fuel product day and night

2. Large capacity(10-30tons tire/plastic per day), high oil yield, good oil quality, high profit.

3. Low cost in operation. No need energy to heat the reactor, generated syn gas is enough, less manpower.

4. High quality and environment, to meet your strict emission standards.

5. Safety. Mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, guarantee 100% safety in the continuous tyre to oil recycling process.

DOING - Fully continuous tire pyrolysis oil (TPO) units In India

In accordance with Indian environmental regulations, Henan DOING supplies new type continuous pyrolysis plant in India to achieve non-pollution production process. Fully continuous tyre pyrolysis oil (TPO) units in India designed by DOING adapts to local environmental requirements. Henan DOING can offer turnkey project for you. We will help you to modify pyrolysis plant structure and equip spare parts. In this way, the whole tyre pyrolyzing process will not pollute the environment and had negative impact on the health of the facilities’ workers. Seek out fully continuous pyrolysis plant cost estimate in India here.

Waste oil to diesel distillation plant

DOING GROUP - Pyrolysis oil to Diesel Fuel Refining Machine

Whatsapp/Tel: +86 13526692320 E-mail: oilmachine@wastetireoil.com

Henan Doing Company has been engaged inwaste to diesel oil recycling machine R&D, fabrication and exportation for 13+ years. From waste tire plastic pyrolysis plant, to Pyrolysis Oil Refining Machine, we can customize them for you at favorable prices.

DOING pyrolysis oil refining machine has high oil yield of 85%. It can extract good quality&bright color diesel from pyrolysis oil. The pyrolysis oil to diesel refining process is: heating-distillation-catalysis-oil gas cooling-further purification.

Click to check: How to convert pyrolysis oil to diesel fuel by pyrolysis oil refining machine?

https://youtu.be/WTfYm99TH4A?si=kWnzdCiStu4076WU

Mutiple uses: this machine can also be used to refine waste engine oil, old lube oil, used motor oil, liquild oil sludge, etc.

More machine details and free quotations about Pyrolysis Oil Refining Machine, welcome to consult us.

Official Web:http://www.wasteoiltodieseloil.comTyre Doubling Tripling Packing Machine

Doing Company - Model Tyre doubling machine - Tyre doubling / unpacking machine

The tyre doubling / unpacking machine has several main advantages as below:

For some tyre dealers, they want to keep complete tyres for further use. So they don't want to cut tires for better storing and transport, then they can use the tyre doubling & unpacking machine to make several tyres nested together firstly. After transport, they can unpack the tyres to normal for further use.

This tyre doubling / unpacking machine doesn't need electricity to work. It powered by compressed air. which can save so much energy.

Tyre doubling / unpacking machine is easier to operate and more efficiently. It can be operated by only one worker, which can make 3 tires nested together within 1 minutes.

So in conclusion, the tyre doubling / unpacking machine can not only save the storage and transport cost, but also save the energy, the labour and the time.Waste Tyre Pyrolysis Plant

DOING - Model DY - Eco-Friendly Waste Rubber Tires From Truck Car and Motorcycle Pyrolysis for Fuel Oil Recovery 100kg Small-Scale Pyrolysis Unit

Skid-mounted Pyrolysis Plant Unit: 100KG/D, 500KG/D, etc.

Equipment Advantages: Free installation, Cost saving, Easy handling, Tests available

Small footprint, occupying approximately 10-20 square meters.

Relatively simple operation and easy maintenance.

Convenient for transportation and installation.

Lower investment cost.

Our pyrolysis plant can process a wide variety of raw materials, including waste tires, plastics, rubber, oil sludge, aluminum-plastic composites, medical waste, municipal solid waste, acrylics, resin powder, fiberglass, plexiglass, epoxy resin, photovoltaic panels, high-temperature machine head materials, rosin, diatomaceous earth, and more.