IEEMA products

Cable

Capacitor and Power Quality

India’s Capacitor Industry – A Journey beyond Reactive Power. India as a country has witnessed unprecedented change in last 30 years for Electrical Power. It is a journey where expectations have moved from Power Availability to Power Quality. Capacitor has all along been part of this journey and kept upgrading and adapting based on the customer requirements & application needs. Constituents of Industry - Capacitor and Power Quality division predominantly represents AC Capacitors popularly known as condensers, LV Power Capacitors, MV/HV Power Capacitors, LV/MV Automatic Power Factor Correction solutions, Allied products like Reactors-Thyristor Switches-Automatic Power Factor Correction Relays-Vacuum Contactor- Capacitor Duty Contactors. More advance technology products like Active Harmonic Filters, Static VAR Compensators/ Hybrid VAR Compensators. Application specific products like High Frequency Induction Furnace Capacitors, DC capacitors and more.

Conductor

For Transmission of power to the end user there is huge and complex network of conductors between the generating stations and the consumers. These networks together form a complete Transmission and Distribution system but the function of both the systems is marginally different from each other. The main function of Transmission system is to deliver bulk power from generating stations to the load centers and large industrial consumers who are residing beyond the economical service range of regular primary distribution lines. The power is further stepped down in substations where it is distributed to domestic and commercial users. The power can be transmitted either employing overhead system or underground system.

Distribution Transformer

Distribution Transformers play a very important and vital role in delivering electricity to the last mile. It can be rightly said that the Distribution industry is bringing light in the life of the people. The thrust by the Indian Government to provide quality power to each village and every household through various schemes of electrification like DDUGJY/ IPDS/ RAPDRP/ Saubhagya has given a huge fillip to the demand of distribution transformers all over India. The demand of Distribution transformers is catered majorly by the domestic Industry and the import of transformers is very marginal/ project specific. The Industry is dominated by unorganised MSME units which are spread all over India and are mainly supplying to their state utilities. There are large scale units also which apart from having Pan India presence are also engaged in export of transformers.

e-Mobility and Charging Infrastructure ?

Electrical Insulating Material ?

Energy Meter

IEEMA members hold 85% of the total market share of Meter Industry and combined revenue is around INR. 3000 Crore. IEEMA Meter division has more than 50 members and we produce more than 25 million meters annually. All these end to end activity –design, development, roduction, testing are done in house. Our products are truly 100% made in India products. Metering industry is very active and providing full support to the vision of Hon’ble Power Minister for rollout of smart meters in the country. We are also addressing the various industry issues to different stake holders from time to time. The industry is ready with Smart Metering solutions for the Ministry of Power’s plan to roll out large scale Smart Meters.

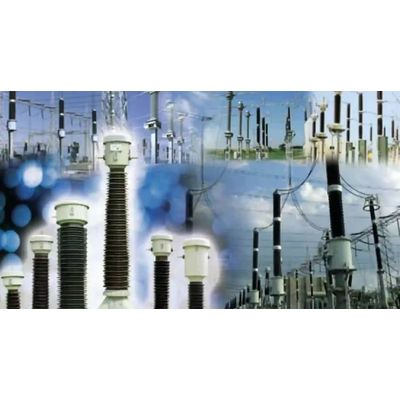

Insulators

Insulators are used in power transmission overhead lines to provide mechanical support and electrical isolation. They are classified on the basis of material as well as voltage levels. There are broadly three types of insulators on the basis of dielectric material – Ceramic/Porcelain insulators, Composite/ Polymer insulators and Glass insulators. As the voltage level increases the size (length) of the insulator required is large and vice-a-versa is also true. The insulators are generally designed based on mechanical and electrical requirements considering altitude, load application, pollution level. The shape of insulators is influenced by considering electrical, mechanical requirements. The insulators are used in transmission and distribution network, electrical traction system (railway, trolley bus, tramway etc.) telegraph and telephone lines or in equipments like Surge arresters, circuit breakers and instrument transformers.

Instrument Transformers

The Instrument Transformers industry in India manufactures current transformers and voltage transformers of various rating from 0.66 kV to 765 kV, for indoor and outdoor applications. The industry has also demonstrated its capabilities by manufacturing 1200 kV CVT for 1200 kV test station by PowerGrid at Bina, Madhya Pradesh. However the industry is witnessing some change in 765 kV segment, mainly due to shift from AIS to GIS. The division is very active and works together in the interest of the industry. TECH-IT is the brand developed by the division which is an international conference on instrument transformers. Keeping up with the covid lockdown times, the division has taken an initiative to impart technical knowledge to all the stakeholders and is organising TECH-IT Tutorials, which are subject specific webinars.