- Home

- Companies

- Igniss Energy

- Products

Igniss Energy products

Igniss - Rotary Kiln Incinerator

The rotary kiln incinerator is manufactured with a rotating combustion chamber that keeps waste moving, thereby allowing it to vaporize for easier burning. Types of waste treated in a rotary kiln incinerator.

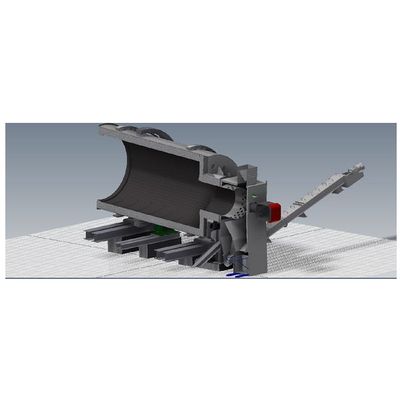

Igniss - Grate Incinerator for Communal Waste

Domestic or communal waste is, afther recycling techniques, still 30% of the total amount rejected by the community. This goes into the grate incinerator and this waste has enough caloric value to burn without support fuel. The starting up of the incinerator is done with support burners untill the fournice has a high temperature: +/-950 degree Celcius.

Igniss - Fluidized Bed Incinerator

The combustion chamber is full of floating particles, like ash and kind of small stones, and in the floating area is the waste mix burning. At the bottom in the combustion chamber there is a gas/air mix injected. The amount of air/gas is maintaining the combustion process. This type of incinerator is made for waste or fuel which is able to float. For this the waste is like a homogeneous mixture. Like WWTP sludge, crushed coal or carbon, MBM (meat and bone meal), etc. If the waste would not be homogeneous it there would be part which are falling, parts which are floating and parts which are flying away by pneumatic transport. For this type of waste exist fluidized bed incinerators with a kind of basket. This basket fluidized bed applications are only in a few cases justified and correct working.

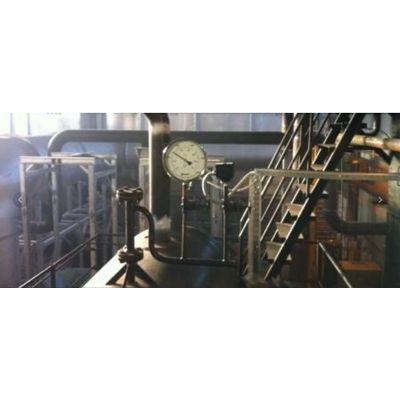

Igniss - Energy Recovery Incinerators

The heat recovery of a waste incinerator we call just heat recovery system. If we can produce electricity from the heat recovery system, we have an electrical power generation system. The combination of heat recovery and power recovery is COGENERATION system.

Igniss - Material Recovery Incinerators

Material recovery is a source of income for an incinerator. The recovered materials are mostly in the ash of the combustion chamber, or in the flue gas. The evaporation temperature and the melting temperature of the component is defining if it stays in the ash or it will travel with the flue gas to the filters and the ash hoppers.