John Zink Hamworthy Combustion products

Process Burners

John Zink - Model COOLstar+ - Process Burner for Ethylene

The new COOLstar+ process burner for ethylene applications from John Zink combines the field-proven reliability of a trusted platform with innovative technology to raise the bar for combustion equipment performance. Its easy-to-retrofit design unlocks increased productivity and reliable emissions control without the need for costly system overhauls. And with stable operation across diverse gas blends and operating conditions, increased fired duty density, and improved burner reliability with fewer maintenance demands, COOLstar+ maximizes long-term value through sustainable innovation.

John Zink - Model COOLstar+ - Process Burner for Refining

The new COOLstar® process burner combines the proven reliability of a trusted platform with advanced innovation to raise the bar for combustion performance in refining applications.

John Zink - Model SOLEX - Process Burner

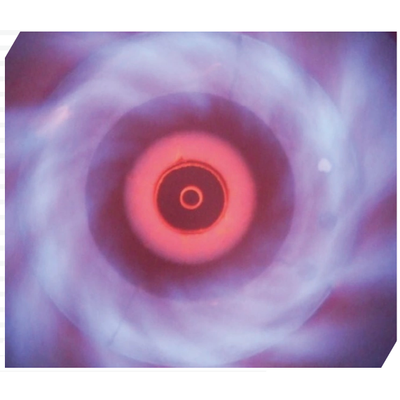

Our SOLEX Burner is designed with two combustion zones to deliver ultra-low emissions and high efficiency, including single-digit NOx emissions and near-zero CO emissions at startup.

John-Zink - Model COOLstar - Process Burner

The COOLstar Burner from John Zink is designed for ultra-low NOx gas firing applications and delivers stable flames and NOx emissions as low as 15 ppm.

John-Zink - Model WALFIRE - Radiant Wall Burner

Our WALFIRE Radiant Wall Burner is the highest hydrogen-compatible radiant wall burner available on the market, ensuring safe and efficient combustion.

John Zink - Model LPMW - Radiant Wall Burner

The LPMW Radiant Wall Burner from John Zink is a lean premix radiant wall burner designed to provide ultra-low NOx emissions and reliable performance across various industrial applications.

John Zink - Model LN-SFR - Process Burner

The John Zink LN-SFR burner is an advanced gas-fired, round flame, low NOx process burner that incorporates cutting-edge technology to achieve reduced emissions and high-efficiency performance.

Power Burners

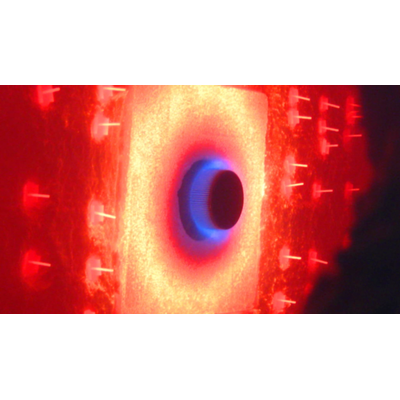

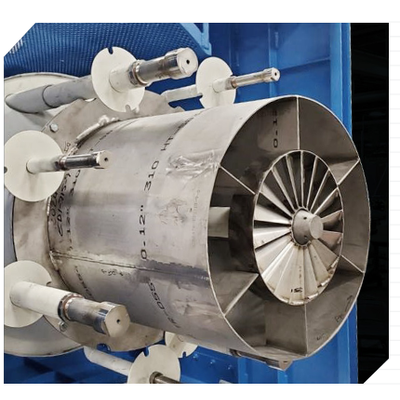

John Zink - Model ECOjet Edge+ - Ultra-Low NOx Boiler Burner

The Next Evolution in Ultra-Low NOx Combustion — Now as Low as 15 ppm Without FGR. Building on the proven success of the ECOjet and ECOjet Edge platforms, ECOjet® Edge+ is John Zink`s flagship ultra-low NOx boiler burner technology. With more than 350 ECOjet family installations worldwide, it carries forward the reliability and partnership customers expect from John Zink, backed by lifecycle support that ensures performance well beyond installation. Designed to anticipate regulatory shifts and evolving operating demands, ECOjet Edge+ is capable of achieving as low as 15 ppm NOx without FGR while maintaining the stability, turndown, and durability that make ECOjet burners trusted worldwide. It is more than future-ready. It is hydrogen proven, with active installations firing 100% natural gas to 100% hydrogen.

John-Zink - Rapid Mix Burner (RMB)

The Rapid Mix Burner (RMB) by John Zink delivers ultra-low NOx emissions with advanced mixing technology, offering a cost-effective solution for thermal oxidizers and incinerators.

Flare Systems

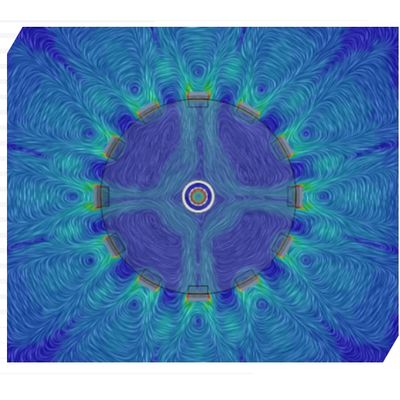

John Zink - Combustion Flare Tip for Low BTU Industrial Gases

John Zink's Extremely Low BTU Flare Tip sets a new standard in flare technology by ensuring stable, smokeless combustion for gases with low heating values, as low as 110 BTU/scf. This flare tip has been developed through collaboration with PTTEP and integrates advanced design features like assist fire elements and spokes to enhance flame stability and optimize combustion efficiency. It has been validated through computational fluid dynamics (CFD) simulations and prototype testing, proving its mechanical integrity and performance in both brownfield and greenfield applications. Especially beneficial for offshore oil and gas production, it minimizes hydrocarbon flaring, reduces greenhouse gas emissions, and maximizes reservoir recovery, offering substantial environmental and economic advantages. This innovation highlights John Zink's commitment to responsible industrial operations and energy efficiency.