KLEVE Solar Sp. z o.o. products

Ground Systems – Photovoltaic Farms

KLEVE - Mounting System for Photovoltaic Farms

The KLEVE PVN-2V system serves as a robust ground-mounted structure specifically designed for photovoltaic farms. Its construction primarily utilizes structural steel, enhanced for durability, and is protected by Arcelor Mittal's Magnelis anti-corrosion coating. This setup accommodates a flexible angle range between 10 to 35 degrees to optimize solar capture efficiency. Additionally, the system supports a vertical module arrangement in two rows, facilitating adaptability to different project requirements. This makes the PVN-2V a versatile choice for large-scale solar energy projects, combining reliability with efficient space utilization to meet the demands of modern photovoltaic installations.

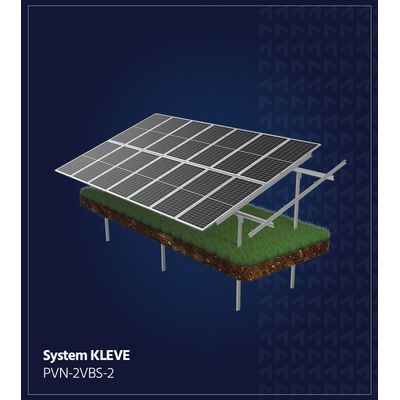

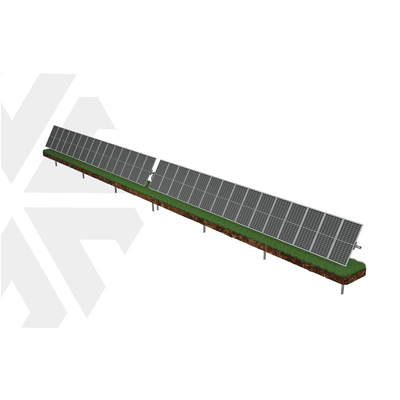

KLEVE - Ground-Mounted Photovoltaic System

The KLEVE PVN-2VBS-2 system is a robust ground-mounted structure specifically designed for photovoltaic farms. It is constructed with structural steel that offers enhanced durability, ensuring long-term stability and performance in various environmental conditions. The system features an Arcelor Mittal Magnelis anti-corrosion coating, providing increased protection against the elements. The PVN-2VBS-2 accommodates a module arrangement in a vertical layout with two rows, suitable for bifacial panels, optimizing sunlight capture. With a tilting angle adjustable between 10 and 35 degrees, the system allows for tailored configurations to maximize energy generation based on geographical latitude and sun exposure. These design elements ensure a balance between operational efficiency and structural integrity.KLEVE - Ground-Mounted Structure for Photovoltaic Farms

The KLEVE PVN-2VBSS-2 system is specifically engineered for ground-mounted photovoltaic farms, offering robust structural support for solar modules. The system features durable structural steel, designed to withstand various environmental conditions, extending the operational life of solar installations. Its Arcelor Mittal Magnelis anti-corrosion coating enhances resistance against corrosion, ensuring long-term performance and reliability. The structure supports an angle of 20-30°, optimizing solar exposure and energy capture. It is configured for a vertical module arrangement in two rows, and is compatible with bifacial modules, which can generate energy from both sides, improving overall energy yield. KLEVE's focus on enhancing photovoltaic farm operations through meticulously designed systems positions it as a reliable partner for solar energy projects.

Tracking Systems – PV Tracker

KLEVE - Single-Axis Photovoltaic Tracker

KLEVE Sp. z o.o. offers an advanced photovoltaic tracking system designed to enhance the efficiency of solar installations. The KLEVE photovoltaic tracker is a single-axis system that optimizes solar energy capture by aligning the photovoltaic panels with the sun's trajectory throughout the day. This tracker is equipped with a robust astronomical tracking algorithm and a 3D backtracking system, adaptable to various terrains. It utilizes independent geared motors, allowing for quick installation without the need for welding or drilling. The system's structural components are HDG or ZM-coated to ensure durability and feature maintenance-free plastic bearings. The minimum clearance from the ground is 300-500 mm, adjustable based on snow zone requirements. Other features include adaptive tracking for uneven terrain and configurable angle limits to respond to wind speeds. These characteristics improve both the performance and reliability of photovoltaic installations, making them a sustainable investment in solar energy.

KLEVE - Photovoltaic Tracker Parameters

The horizontal, single-axis photovoltaic tracker from KLEVE [solar] features an astronomical tracking algorithm with 3d backtracking system, with terrain-adjustable capabilities. Driven by independent geared motors for each tracker, it is designed for quick and easy installation, with no welding and no drilling. The KLEVE photovoltaic tracker is HDG or ZM-coated structural steel and maintenance-free plastic bearings. The minimum clearance between the panel and the ground is 300-500 mm, depending on the snow zone.