Kovalus Separation Solutions, Inc. products

Ion Exchange - AnoPur, CER and DPU Systems

Kovalus - Model CER - Caustic Etch Recovery System

Etching or chemical milling with caustic soda can often be the greatest operating expense in aluminum anodizing. Our CER Caustic Etch Recovery System continuously crystallizes and removes dissolved aluminum from caustic soda etchants and returns the caustic to the etching/milling tanks for reuse resulting in reduced chemical costs, waste treatment costs, and labor requirements. The separated aluminum trihydrate crystal contains a marketable and salable value.

Evaporation & Drying - Drying Components

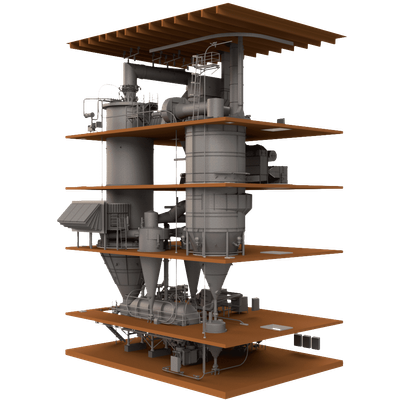

Kovalus Relco - Tall Form Bustle Dryer

RELCO’s Tall Form Bustle Dryer is customized to fit your product requirements including: NFDM, Codex Skim, WMP, WPC34-80, WPI, Buttermilk, MPC80, MPI, IMF (Infant Milk Formulas), Microparticulated WPC, Pro-cream, Yeasts, Encapsulated Powders, Blood, and Sweet Whey. The Tall Form Bustle Dryer is optimized with a vertical hot air distributor, vibrating well mixed and plug flow beds and baghouse. Other features can be added for specific customer requirements and include: multi fuel indirect fired heater, timing belt, cyclones, baghouse fines retention bin, heat recovery, dual feed system, retractable cip nozzles, lecithination and spray nozzle cameras.

Evaporation & Drying - Drying Components - Heat Recovery

Kovalus - Air Liquid to Air Heat Recovery Panel

Exhaust air temperatures alarms activate the fire deluge. Stand-alone Relco Fire deluge control panel.

Kovalus - Air to Air Heat Recovery Panel

Recovering heat from the dryer exhaust air for pre-heating incoming process air. Uses a water circulation loop for heat exchange.

Evaporation & Drying - Drying Components - Indirect Gas Burner Styles

Kovalus - Shell in Shell Style Indirect Gas Burner

An indirect gas burner (natural or propane gas) for heating the main drying air.

Kovalus - Envelope Style Indirect Gas Burner

An indirect gas burner (natural or propane gas) for heating the main drying air.

Kovalus - Direct Burner

A direct gas burner (natural or propane gas) for heating the main drying air.

Eco-Tec BgPur - Biogas Hydrogen Sulfide (H2S) Removal

BgPur is Eco-Tec’s proven H2S removal system for treatment of biogas from anaerobic digesters or landfills. The system is capable of treating biogas with H2S concentrations of a few hundred ppmv to over 30,000 ppmv (3%) while reducing the H2S to a just a few ppm to meet downstream requirements for power generation or heating fuel, or to be sold for pipeline or transportation fuel.

Recoflo Recoflo Triflo - Demineralizer Produces High Purity Water Feeding Critical and Super Critical Boilers

Eco-Tec’s TriFlo Demineralizer produces the ultrapure water (i.e. conductivity of less than 0.1 μS/cm) often required to feed critical and super critical boilers. This is achieved economically with stable and robust process equipment from feed water containing up to 450 ppm of total dissolved solids. Ultrapure water can be achieved by simply adding an additional cation resin bed as a polisher after the usual two-bed demineralizer to remove residual sodium ions. The TriFlo Demineralizer can provide solutions for applications requiring high purity water in the range of 10 – 18.0 ohm.cm resistivities.