- Home

- Companies

- Louis Allis

- Products

Louis Allis products

Louis Allis - Factory Recertified Electric Motors

Louis Allis specializes in offering a cost-effective solution with their Factory Recertified Electric Motors. These motors are ideal for situations requiring immediate replacement due to unforeseen failures, eliminating the long lead times associated with new builds. The recertification program modifies surplus motors both mechanically and electrically to fit and function like the existing motor, keeping budget constraints in mind. Additionally, they can refurbish legacy motors to original equipment manufacturer specifications by replacing all internal components while retaining the original frame. Certified for MIL-STD-2037 Navy Sealed System Windings, their motors meet stringent U.S. Navy standards. With every recertified motor backed by a one-year warranty, clients across diverse industries can trust Louis Allis for reliable and swift solutions, ensuring minimal downtime and enhanced operational efficiency.Louis Allis - Electric Motor Replacement Parts

Louis Allis offers an extensive selection of electric motor replacement parts tailored for both legacy Louis Allis motors and various other OEM parts. The product range covers basic components such as bearings, oil sight gages, terminal boxes, and fans, expanding to more intricate items like replacement housings, bearing brackets, shafts, rotor assemblies, stator cores, and hood assemblies. Recognizing the critical nature of minimal downtime in industrial applications, Louis Allis also supplies factory recertified motors, providing a speedy and efficient solution for scenarios where repair is not feasible. Quality underpins all operations at Louis Allis, with a commitment to excellence evident in their ISO 9001:2015 certified facility, known for both new motor manufacturing and meticulous motor repairs. The company is equipped to service a diverse range of motors, offering dependable repair and recertification programs to ensure operational reliability.Specialty Motors

Louis Allis - High-Voltage Custom Electric Ball Mill Motors

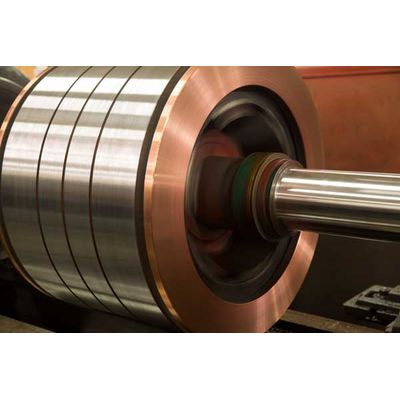

Ball mills are essential industrial machines employed extensively in processes where materials need to be ground or blended, especially in industries such as cement, coal, and textiles. At the core of a ball mill's efficiency is its electric motor, which drives the grinding mechanism. Louis Allis specializes in designing and manufacturing high-voltage electric motors tailored specifically for these applications. Unlike generic off-the-shelf motors, these custom motors are engineered for superior reliability and reduced downtime. The motors can endure the demanding conditions of the ball mill environment, ensuring consistent performance. With over a century of expertise, Louis Allis addresses the challenges of in-place refurbishment, repair, and rewinding of these massive motors, extending their lifespan and operational efficiency. The company’s ISO 9001:2015 certified facility upholds rigorous quality standards during both manufacturing and repair processes, reinforcing its leader position in the electric motor industry.Louis Allis - Electric Motors for Bow Thrusters in Large Vessels

Louis Allis specializes in the design and manufacture of electric motors tailored specifically for maritime use, focusing on bow thrusters for larger offshore vessels. These maneuvering thrusters are paramount for navigating through narrow channels and turbulent coastal waters. Their AC and DC motors are engineered to deliver superior torque and control compared to standard electric motors, ensuring optimal functionality in harsh maritime conditions. Recognized for MIL-STD-2037 Navy Sealed System Windings, Louis Allis certifies that their motors meet stringent US Navy standards. A commitment to quality is demonstrated through their ISO 9001:2015 certification, ensuring reliability whether in new builds or through factory recertification. With over a century of expertise, Louis Allis offers robust solutions to fit specific maritime applications, reducing dependency on tugboats and decreasing port time, effectively optimizing operational efficiency and cost-effectiveness. Their broad capabilities include custom motor designs to replace any original equipment manufacturer motors, providing comprehensive services beyond their specialty products.