Mondragon Assembly, S. Coop. products

Solar Laminators

Lamination is one of the most critical processes in the solar panel manufacturing line; it ensures the quality and durability of the photovoltaic module. To ensure your products are top quality, Mondragon Assembly selects the best solar laminator for the production characteristics defined by the client, offering an optimised production line tailored to your needs.

Framing Equipment

Mondragon Assembly has one of the best framing equipment. Correct framing of the laminates provides mechanical strength to the photovoltaic modules and facilitates their subsequent installation, making it more simple and timely.

Tabber and Stringer

Mondragon Assembly - Single-Track Tabber and Stringers

A high-performance Tabber and Stringer equipped with a single welding tape (Single Track).

Mondragon Assembly - Tabber and Stringer

Mondragon Assembly’s Tabber&Stringer is ergonomic, simple, and has a high production capacity. Thanks to our knowledge and experience in technological processes and solar equipment, our team offers modular designs with advanced functions, low cost and high performance. The Tabber&Stringer has four main remarkable elements: Cell quality control using artificial vision, advanced control of the IR soldering process, servo-drives and up to 5 bus bar ribbon power systems.

Mondragon Assembly - Tabber and Stringer

Very flexible Tabber&Stringer, can make standard modules or special modules with cut cells, for example, very easy to handle and economical with a medium-high production capacity of >40MW/year.

Mondragon Assembly - Tabber and Stringer

Easy and economical Tabber&Stringer with a production capacity of >25 MW/year.

Mondragon Assembly - Tabber and Stringer

Easy and economical Tabber&Stringer with a production capacity of >20MW/year.

Mondragon Assembly - Layup Stringer

The layup manipulates and inspects the strings coming from the Tabber and Stringer using artificial vision and accurately positions them over the glass + EVA. Mondragon Assembly’s different layups adapt to the capacity of each Tabber&Stringer, from the compact machine with layup integrated into the customizable, to the GTS 18 with 6 axle robot, providing an extremely broad variety of options for our clients.

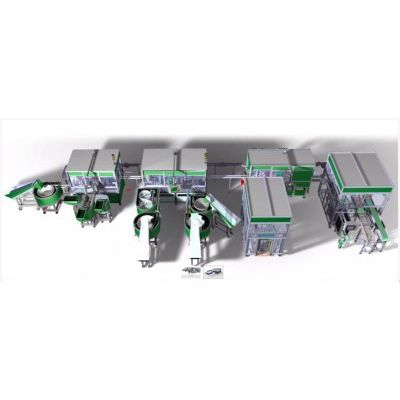

Automation Solutions

Full Automatic Assembly Line

Full automatic turnkey assembly line for the assembly and control of a wide range of products. Our solutions go from the feeding of each individual part to the final packaging of the finished products, along with all the required quality controls. The production can be continuously monitored and saved into MES systems. Mondragon Assembly guarantees the best solution in terms of cost, efficiency and customer service.