OSSBERGER GmbH Co. KG products

Hydropower Turbines

OSSBERGER - Cross-flow Hydro Turbines

The patented OSSBERGER cross-flow turbine works with heads from 2.5 meters up to 200 meters. We developed this turbine especially for small hydropower. It is currently available with outputs of up to 10 megawatts. Even with very low water flows, it reliably delivers energy and copes perfectly with fluctuating water volumes. This is achieved through two cells inside the turbine that can work independently of one another. The small unit already suffices as 5% of the design water quantity to start the turbine. OSSBERGER cross-flow turbines therefore mostly work all year round. Even if other types of turbines have long been idle. By concentrating on the essentials, the original OSSBERGER cross-flow turbine is very robust. Terms of many decades are the rule. The secret of their reliability is simplicity: only three moving parts ensure minimal maintenance and maximum technical reliability.

OSSBERGER - Kaplan Hydro Turbine

When it comes to very small heads, other technical approaches can be advantageous in order to meet the needs of the customer. That is why OSSBERGER plans systems with Kaplan turbines here. The decision on the suitable type of power plant is made following an intensive examination of the customer`s requirements and the planned location.

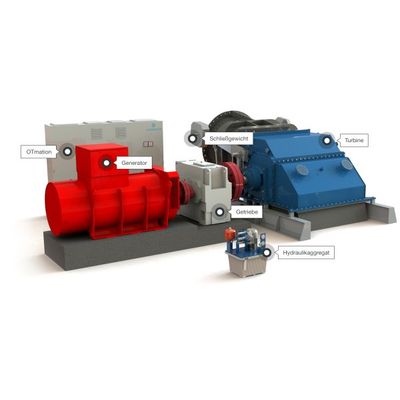

OSSBERGER - Automated Control System

Control is of the utmost importance for the efficient use of a hydropower plant. The system is automatically regulated to ensure optimal yield and is monitored at the same time to prevent damage and downtime. The OSSBERGER portfolio in terms of control technology ranges from the control of a micro-system to the remote control of a power plant with several turbines. Both parallel and island operation can be controlled by the systems. OSSBERGER focuses on the greatest possible efficiency with simultaneous simplicity. The systems can also be operated by non-experts. The use of robust components ensures that the control will function smoothly for many years.

OSSBERGER - Trash Rack Cleaner

Ossberger has also specialized in the construction of stationary and mobile trash rack cleaning systems. They are indispensable in order to secure the electricity production of hydropower plants in the long term. The systems clean the protective screen of the water supply of alluvial debris and thus ensure maximum flow in the turbine. The systems are quick and easy to assemble, particularly reliable and have low drive powers. They are a worthwhile investment for any size of power plant, and they are often amortized after a short time.

Surface Technology/Line Platform

OSSBERGER - Coli-Cleaner

Cleaning:Dry cleaning. Process stages:Dry. Dimensions:0.6 x 0.6 x 2.2 m (wxdxh). Weight:650 kg. Electrical power:approx. 4 kW.

OSSBERGER - Coli-Cleaner

Cleaning: Dry cleaning. Process stages: Dry. Dimensions:1.0 x 1.2 x 1.5 m (wxdxh). Weight: 620 kg. Electrical power:4 kW.

OSSBERGER - Coli-Cleaner

Cleaning: Dry cleaning. Process stages: Dry + warm air. Dimensions: 1.0x1.5x2.4m(wxdxh). Weight: 1200 kg. Electrical power: 6-8 kW.

OSSBERGER - Coli-Cleaner

Cleaning : Dry cleaningPLUS. Process stages: Wet/dry cleaning. Dimensions: 1.0x2.0x2.4m(wxdxh). Weight: 1350 kg. Electrical power: 6-12kW.

OSSBERGE - Coli-Cleaner

Cleaning: DrycleaningPLUS. Process stages: Pre / wet / dry cleaning. Dimensions: 1.0x2.0x2.4m(wxdxh). Weight: 1700 kg. Electrical power: 8-18kW.

Hydropower Trash Rack Cleaner

OSSBERGER - Stationary Hydraulic Hydropower Trash Rack Cleaner

Ossberger developed the stationary, hydraulic trash rack cleaner of type RRH for the automatic cleaning of small and medium-sized trash racks installed at water intakes of channels and storage basins. This machine is equipped with single-arm, wide extending angle booms, on which the cleaning rake is attached perpendicular to the river flow. The boom consists of two arms jointed by a pivoting bearing. Hydraulic cylinders move the rake up and down according to the geometry of the screen. Additionally, the traction arm can be furnished with a telescopic extension; a hydraulic aggregate controls the oil supply.