Precision Combustion, Inc. (PCI) products

Fuel Processor

PCI Microlith - Fuel Processor and Fuel Reformer Systems

Precision Combustion Inc. is developing integrated fuel processor systems to enable fuel cells to operate using a wide range of available fuels ranging from gases (e.g. methane and propane) to conventional liquid fuels (diesel, gasoline and military logistics fuels including JP-8, JP-5, and Jet A) to alternative and unconventional liquid fuels such as biofuels and waste hydrocarbons recovered from industrial processes (e.g. paint solvents). PCI is developing a range of reactors for its fuel processor systems and the fuel cell industry which have been tested in prototype integrations with fuel cell stacks.

PCI - Proton Exchange Membrane Fuel Processor (PEM)

PCI is developing an integrated fuel processor for liquid fuels for application in PEM and High Temperature PEM fuel cell systems. Building upon its ultra-compact fuel reformer and fuel reforming catalytic reactor technologies, PCI is optimizing its fuel reformer and fuel processor technologies for the size, weight and performance needed to enable liquid-fueled PEM fuel cell systems under multiple Army and Navy programs.

PCI Microlith - Fuel Reforming Catalytic Reactors

PCI is developing several fuel reforming catalytic reactors for integration into fuel processor and fuel cell power systems including: Catalytic Partial Oxidation (CPOX) of methane, propane, gasoline, Jet A, JP-8 and diesel, Autothermal Reforming (ATR) of gasoline, Jet A, JP-5, JP-8 and diesel, Oxidative Steam Reforming (OSR) of methanol, Steam Reforming (SR) of methane, diesel.

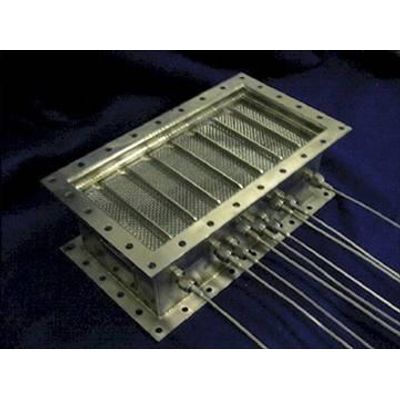

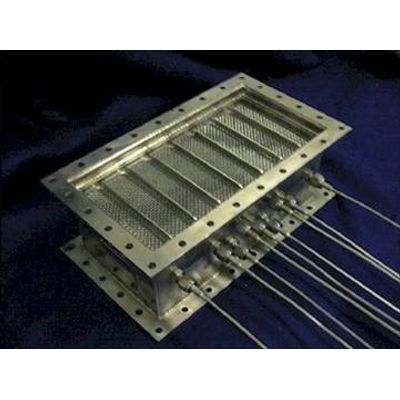

PCI - Water Gas Shift and Prox Fuel Processor Catalytic Reactors

PCI is developing water gas shift and selective CO oxidation (aka PROX) catalytic reactors for integration into fuel processing and fuel cell power generation systems. PCI`s Water Gas Shift and PROX technologies developed under NSF, Navy and internal programs have demonstrated highly selective conversion of CO in an extremely small package. The Water Gas Shift technology reduces CO concentration in the reformate stream to ~ 0.5% (dependant upon system specifications) with low methanation. PCI`s PROX technology further reduces the CO concentration to below 10 ppm, while consuming less than 3% of the hydrogen in the reformate.

Catalytic Burners and Oxidizers

PCI - Model WGS and PROX - Catalytic Burner

PCI is developing water gas shift and selective CO oxidation (aka PROX) catalytic reactors for integration into fuel processing and fuel cell power generation systems. PCI’s Water Gas Shift and PROX technologies developed under NSF, Navy and internal programs have demonstrated highly selective conversion of CO in an extremely small package. The Water Gas Shift technology reduces CO concentration in the reformate stream to ~ 0.5% (dependant upon system specifications) with low methanation. PCI’s PROX technology further reduces the CO concentration to below 10 ppm, while consuming less than 3% of the hydrogen in the reformate. Technology attributes are highlighted in the table below.

PCI - Fuel Cell Oxidizer System

The rapidly advancing fuel cell industry is persistently striving to become safer, less costly, and more efficient each day. PCI is supporting that mission with our unique burner and oxidizer technologies. We are helping to pioneer fuel cell development by adapting our innovative burners to effectively complement emerging advances in the field.

Other Products

PCI Microlith - Model SOFC - Ultra-Compact Solid Oxide Fuel Cell Systems

PCI is developing a family of ultra-compact solid oxide fuel cell power generation systems. These systems utilize Microlith reformers to operate on logistics fuels and methane used today, biofuels of tomorrow and sustainable fuels of the near future. PCI’s systems utilize its advanced solid oxide fuel cell technology and are ideal for mobility applications as they are compact, lightweight and can start and be generating power in under an hour today, with an objective to start and be operating in minutes in the near future. PCI’s technology is readily scalable to small and large systems. This enables PCI to design solutions for a variety of industrial and government customers.

PCI - Tactical Power Generation System

PCI has developed a family of soldier power gensets targeted to fill the capability gap for lightweight, portable power generation. These generators use COTS gasoline engines that are modified to use tactical fuels (JP-8, Jet A JP-5, DF2, etc.) using PCI’s fuel conditioning technology. These devices have been tested to meet the harsh environmental and operations demands of the US Military and are easy to start, operate and maintain. These generators have been selected for development by the US Army for their Platoon Power Generation (PPG) and Small Tactical Electric Power (STEP) Lightweight programs.

PCI - Internal Combustion Engine System

PCI’s Internal Combustion Engine fuel augmentation system takes a slipstream of incoming fuel and creates a high octane, highly combustible mixture that is injected into the engine with standard fuel. This method positively impacts engine performance, reduces emissions and enables improved engine efficiency. PCI’s engine augmentation has proven performance on both spark and compression ignition engine systems. At the core is PCI’s Microlith catalytic reactor: an ultra-short-channel, low-thermal-mass substrate that delivers high mass/heat transfer with very low pressure drop for millisecond-scale reforming in a compact package. PCI’s waterless, sulfur-tolerant approach has demonstrated efficient gasoline and diesel reforming while avoiding coking. The catalytic reactor increases the octane of low octane fuels, thus enabling them to be utilized in spark ignited engines.