- AirScience Biogas and Landfill Gas Flares

- Purifications - AirScience Desulfurization System

- Purifications - AirScience Dehumidification System

- Purifications - AirScience Siloxanes & VOC Removal System

- Purifications - AirScience Oxygen Depletion System

- AirScience Technologies - Air Pollution Control

- Technologies

Pyro Green-Gas (formerly known as AirScience Technologies Inc.) products

AirScience Biogas and Landfill Gas Flares

AirScience - Biogas Flares

Anaerobic Digester (AD) biogas applications: For AD biogas applications enclosed flame flares are used to burn excess biogas from the process as well as to burn the full biogas production while the downstream biogas valorization system is stopped for maintenance or emergency conditions. The exhaust gas emissions meet the most stringent North American environmental requirements. This is achieved with combustion temperatures between 1000C and 1200C. The patented high mix, low NOx burner provides the lowest NOx emissions available on the market.

Purifications - AirScience Desulfurization System

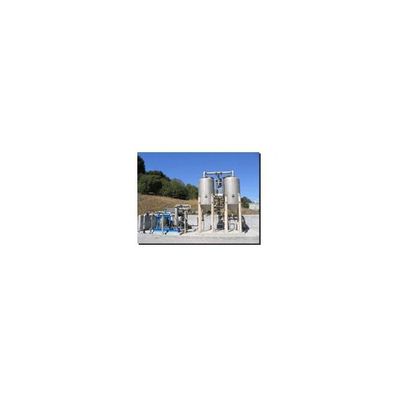

AirScience - Model AST-AC/S01 - Biogas Dry Desulfurization Process System

Iron based desulfurization media has low cost and high desulfurization capacity as its main advantage, however the chemical reaction occurring during the capture of hydrogen sulfide tends to agglomerate the media pellets in larger chunks which render the spent media removal a time consuming chore. For this reason the tendency for landfill gas and biogas desulfurization has been to use activated carbon as the favored desulfurization media.

Purifications - AirScience Dehumidification System

AirScience - Model VPSA - Vacuum Pressure Swing Adsorption Process System

This process is primarily used for the dehumidification of biogas destined to the production of compressed natural gas (CNG) whether for transportation CNG or pipeline CNG. The process is very similar to the VSA process with the exception that the feed gas is under pressure and that the desorption sequence is designed to minimize the loss of methane as well as the energy usage (loss of pressure).

Purifications - AirScience Siloxanes & VOC Removal System

AirScience - Model TSA - Thermal Swing Adsorption Process System

This is the most effective siloxanes and VOCs removal system. It combines the removal efficiency of the activated carbon technology with the low operating cost of the VSA system. TSA can treat high loads of siloxanes and VOCs and its thermal desorption process assures that the adsorbent will have an extended usable life.

Purifications - AirScience Oxygen Depletion System

AirScience DeOxo - Oxygen Depletion Process Unit

AirScience experience with oxidation with precious metal catalyst goes back to the early years of the company with the supply of large catalytic reactors for the oxidation of hydrogen bromide (HBr) in the purified terephtalatic acid (PTA) industry. Such as the PTA plants in Montreal, Canada and Altamira, Mexico have used AirScience CaTox units for many years.

AirScience Technologies - Air Pollution Control

AirScience - Gas Dryers System

Wet process gas enters a coalescing pre-filter, then passes through the inlet valve assembly and is directed towards chamber 1 where the clean gas passes upward through the desiccant. Gas drying is doneby adsorption. Dry gas from chamber 1 outlet passes through the valve assembly and through the after-filter to the dry gas receiver tank. While gas is being dried in chamber 1, the desiccant in chamber 2 which has been humidified in the previous cycle, is being simultaneously regenerated. Chamber 2 is de-pressurized, in the downward direction, and the vent gas is released to atmosphere through a purge valve.

Technologies

AirScience - Biogas to Compressed Natural Gas

Converting biogas to transportation fuel as compressed natural gas (CNG) is happening today. It is generating far more revenue per cubic meter of biogas than steam or electricity generation. It is the ultimate in the valorization of biogas.

AirScience TerraGas - Biogas to High Purity Hydrogen

The Terragas process jointly developed by Unitel Technologies and AirScience Technologies, converts biogas from municipal solid waste landfills, anaerobic digesters of waste water treatment plants and other sources to high purity hydrogen.

AirScience - SMR Hydrogen Production

Hydrogen production through Steam Methanol Reforming (SMR). The methanol feedstock is mixed with water in specified ratio and pressurized. This mixture is passed through evaporator, metering pump and super heater. The hot gas mixture is then fed into a catalytic reactor. The reaction of methanol reforming and the shift reaction, takes place in the catalytic reactor of fixed beds simultaneously to form a mixture of H2 and CO2. Hydrogen is then extracted using the Pressure Swing Adsorption process. AirScience builds hydrogen production plants using methanol or methane as feedstock. Plant capacity is available from a few hundred cubic meter per hour to several thousands.

AirScience - Process Gas Desulfurization Unit

THE SULFOX REG PROCESS for 0,5 to 3.0 g/Nm³ Concentrations: The SulfoxREG is a gas desulfurization process that convert sulfur in raw gas to concentrated sulfuric acid. The SulfoxREG process is designed for treatment of gas having H2S and CS2 concentrations from 0,5 to 3.0 g/Nm³ (in total). Using a highly efficient regenerative catalytic oxidizer system the plant can be operated without additional fuel or electric energy even at low concentrations.The concentration of the sulfuric acid produced is in the 50% range.