- Home

- Companies

- RUBIG GmbH & Co KG

- Products

RUBIG GmbH & Co KG products

Industrial Furnaces - RUBIG Industrial Furnaces - MICROPULS® Plasma Nitriding and Coating Furnaces

RUBIG MICROPULS - Plasma Nitriding Furnace

RUBIG’s plasma nitriding system offers our partners the optimum in nitriding technology. We cover industries such as automotive and job-shop heat treatment right up to aerospace and wind energy. Continuous advancements make the RUBIG plasma nitriding system the ideal solution for premium applications. MICROPULS® Everest also helps you to maximize your profit by redesigning your heat treatment strategy.

RUBIG MICROPULS - Coating Furnace

MICROPULS® Procoat is the optimum system solution in the area of hard coatings. From mold making and job-shop coating to component coating – the MICROPULS® Procoat system provides the most advantageous solution in the industrial value chain.

RUBIG MICROPULS - DLC Coating Furnace

With the MICROPULS® Diamond Xtended system, RUBIG offers one of the most innovative system solutions in the field of DLC coating technology. Customers from the hydraulics, defense and drive technology sectors take full advantage of the benefits that our Diamond Xtended solution has to offer.

Industrial Furnaces - RUBIG Industrial Furnaces - MICROPULS® Plasma Generator

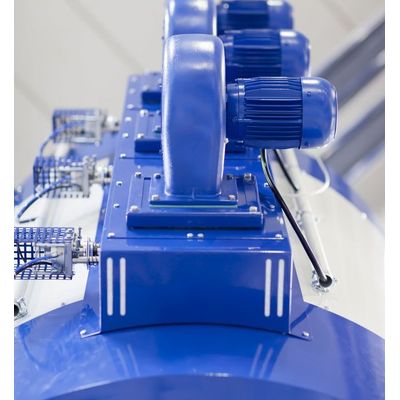

RUBIG MICROPULS - Plasma Generators

The RUBIG plasma generator is the heart of every RUBIG MICROPULS® series system and, as the name indicates, generates plasma. Plasma, the 4th state of matter beyond solid, liquid and gaseous states is produced when very large quantities of energy are added to a gas. This can be achieved either by heat, radiation, or as in the case of the RUBIG generator, using electrical voltage. The recipient wall provides the anode; the components the cathode. On their way from the cathode to the anode, electrons collide with (process gas) molecules. This collision breaks the gas molecules apart, catapulting electrons out of the shell. As these collide with other gas molecules, and the fission process repeats, the residual ionised gas molecules move towards the components and initiate the sputtering process.