SCHMIDTSCHE SCHACK, PART OF THE ARVOS GROUP products

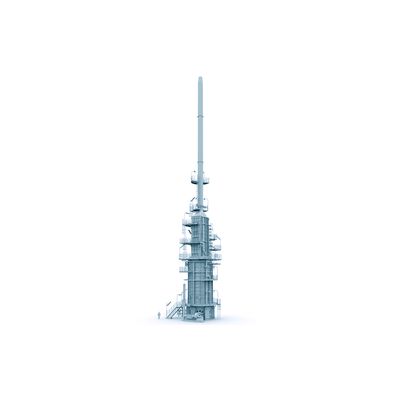

SCHACK - Fired Heaters

Fired heaters are essential and important major pieces of equipment in a process plant. SCHACK® Fired Heaters are designed exactly for your individual requirements, resulting in a safe, efficient and highly reliable heater design. This leads to an optimization in operating costs and fewer operational issues.

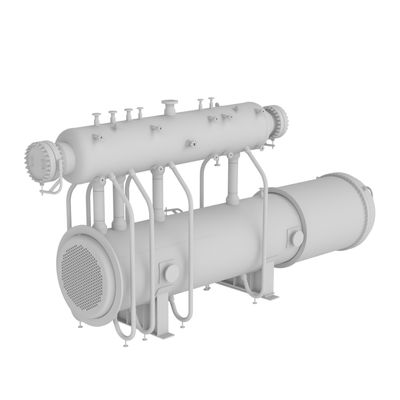

Waste Heat Boilers

SCHMIDTSCHE SCHACK - Waste Heat Boiler Fire Tube-Type

The temperature inside a Claus furnace is often maintained above 1,050 °C (1,922 °F). The SCHMIDT’SCHE Waste Heat Boiler downstream the combustion furnace cools the hot gases and at the same time recovers valuable energy.

SCHACK - Waste Heat Boiler Water Tube-Type

SCHACK Waste Heat Boiler is a valuable application for the sulfuric acid process. Elemental sulfur is oxidized and then converted to sulfuric acid in a catalytic, exothermic process. Several systems are already successfully in operation worldwide. In the cooling sections that are required, several heat exchangers cool the gases to the required temperatures.

Recuperator Solutions

SCHACK - Flue Tube-Type Recuperator

SCHACK® Flue Tube-Type Recuperator is installed to avoid the gases from reaching the cleaning systems with too high temperatures and at the same time to recover energy from hot flue gases. Read more about our SCHACK® Flue Tube-Type Recuperator solutions for carbon black processes or sludge incineration processes.

SCHACK - Double Shell-Type Recuperator

The SCHACK® Double Shell-Type Recuperator consists of two cylinders which are arranged concentrically. In order to transfer the heat, the design of the radiant recuperators must be able to withstand high flue gas inlet temperature. It is suitable for hearth furnaces in the steel industry as well as glass and aluminium furnaces and can also be applied to sludge incineration processes.

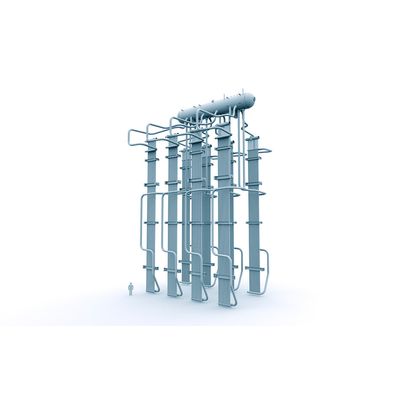

Transfer Line Exchanger

SCHMIDT’SCHE - Transfer Line Exchange

High value and yields of cracked gas: Low pressure drop. Short residence time in tubes.

SCHMIDT’SCHE - Transfer Line Exchange

High value and yields of cracked gas: Low pressure drop. Short residence time in the tubes. Ethylene stabilization temperature reached in one pass.

SCHMIDT’SCHE - Transfer Line Exchange

High value and yields of cracked gas: Low pressure drop. Short residence time through the tubes. Low adiabatic volume and thereby low residence time in the adiabatic zone.

SCHMIDT’SCHE - Transfer Line Exchange

High value and yields of cracked gas: Low adiabatic volume. Short residence time in the adiabatic zone and the tubes.

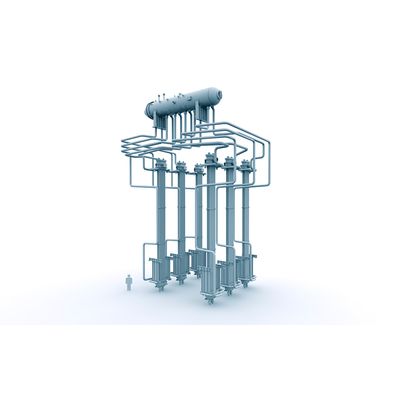

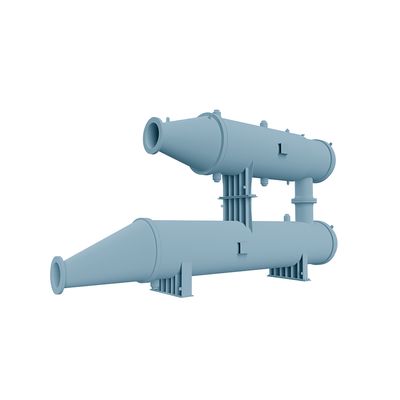

SCHMIDT’SCHE - Secondary & Tertiary Transfer Line Exchange

SCHMIDT’SCHE® Secondary and Tertiary Transfer Line Exchanger, Steam Drum and interconnecting pipework complete your quench system. Many different arrangements of the equipment can be implemented according to our client’s request. On site installation and construction works are therefore minimized. Saving time for planning, installation and erection. Enabling highest safety and reliability.