- Home

- Companies

- Servoday Group

- Products

- Plants & Machinery

- SERVODAY Pellet Plant Project Setup Guide

- Land, Power, Manpower Requirements & Project Timeline for SERVODAY Containerized PELLETBOX Pellet Plant Project

- Land, Power, Manpower Requirements & Project Timeline for SERVODAY Conventional Pellet Plant Project

- SERVODAY Pellet Plant & Machinery: Advantages and Technical Insights

- SERVODAY Frequently Asked Questions: For Biomass and Wood Pellets and Machinery

- INNOVATIVE BIOMASS TURNKEY SOLUTIONS BY SERVODAY

Servoday Group products

SERVODAY - Hammer Mill For Feed, Biomass & Wood Pellet Plant

Hammer Mill for the most demanding applications like Feed, Biomass and Wood Pellet Plant and Grinding industries, the heavy-duty Tear Drop Hammer mill comes in a variety of sizes and models that match all particle size-grinding needs. Tear Drop Hammer Mill built to the highest standards, the heavy duty frame is design to minimize vibration and noise, a robust regrind chamber and pivoting arms type full-access doors, allow the doors to move out of the way during maintenance of Mill. Visit www.woodpellet.in or call +91 7383410723SERVODAY - Ribbon mixer for pellet plant

FEATURES: * Suitable to handle all kind of Biomass Materials with various density and shape. * Recommended for Biomass Pellet Plant * Fabricated with superior quality raw materials and standard bought out items (Gear Box, Motors, Belts & Acceesories) from reputed suppliers only * Robust and sturdy design * High durability due to accurate design and robut construction * Mixing capacity up to 20 TPH * Available in variety of trough and warm (flight) thickness * The Ribbon Mixer is designed for consistent, homogenous batch or continuous blending of powders and granules. It’s performance varies from gentle blending, to high intensity mixing * To provide a homogenous and ‘perfect blend’, a Ribbon Mixing machine will use high-shear choppers, combined with impact. This makes it a very popular choice of mixer, due to the wide range of powders and bulk solids it is capable of handling * This also allows for versatile mixing capabilities.

Servoday Group - Wood & Biomass Pellet Plant

SINGLE SOURCE PRODUCER FOR WOOD - FEED - BIOMASS PELLET PLANTS We supply complete Wood - Feed - Biomass Pellet Production Plants on Turnkey basis, from concept to commissioning, the service include site Layout, Design, Manufacturing, Handling, Storage, Building, Power, Water, Installatiion, Testing, Commissioning, Training and Support. Wood - Feed - Biomass Pellet Production Plants Capacity: 1 Tone Per Hour (TPH) - 5 Tones Per Hour (TPH) 10 Tones Per Hour (TPH) - 20 Tones Per Hour (TPH) 25 Tones Per Hour (TPH) Visit www.woodpellet.in or call +91 7383410723.SERVODAY: - Crafting Excellence for Optimal Pellet Production High-Performance SERVODAY Pellet Mill Rollers for Biomass & Wood Pellets

Explore high-performance SERVODAY Pellet Mill Rollers designed for durability and efficiency in biomass and wood pellet production. Precision-engineered for superior performance. View Details: https://pelletmill.in/spares/pellet-mill-rollersPlants & Machinery

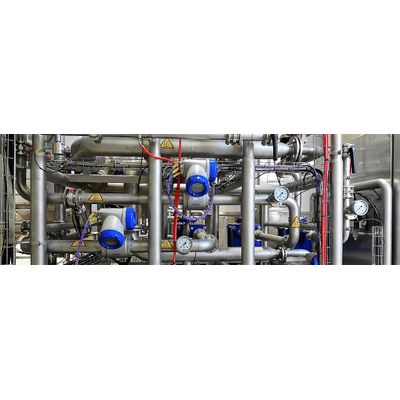

Servoday - Edible & Non-Edible Oil Refining Plant

Our supply of Edible & Non-edible Oil Refining Plant include from concept to commissioning on Turnkey basis, also supply Neutralizer Bleacher Deodorizer Cooler & many more equipments.