SHINEHEAT TECH (SHANGHAI) CORP products

Plate and Gasket Heat Exchanger

SHINEHEAT - Plate Heat Exchanger

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species, either cold or hot. to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system.

SHINEHEAT - Plate Heat Exchanger-Sanitary Application

The Plate Heat Exchanger (Multi-Section) is Widely used in Dairy plant for Pasteurization and Cooling process. During milk Ultra High Temperature Pasteurization, the low temperature milk passed into Heat Recovery Section Plate Heat Exchanger through Balance Tankl and Material Pump2, the milk will be pre-heated there. After pre-heating, the milk will enter into homogenizer for homogenizing. After that, it will enter into Heating Section of Plate Heat Exchanger, and be heat into 137°C. The milk will be insulated 4 second at 137 °C for UHT. After UHT, the milk will enter into Cooling Section of Plate Heat Exchanger. After Cooling, the milk can be packaged. Plate heat exchangers are widely used in the food industry due to their efficient heat transfer capabilities and hygienic design. In particular, they find extensive application in the dairy industry, specifically in the process of pasteurizing milk through the method of high-temperature, short-time (HTST) treatment.

SHINEHEAT - Plate Heat Exchanger-Marine Application

Plate Heat Exchanger is widely apply for Marine Application As to illustrated by following drawing, the main application for Marine Plate Heat Exchanger is "HT Cooler", "LT Cooler" and "Lube Oil Cooler". "HT Cooler" and "LT Cooler" is Primaiy Cooler and Secondary cooler for Jacket Cooling Water from Main Engine System, the Cold Fluid is from Sea Water, so the plates always are Titanmium Plates. "Lube Oil Cooler" is SAE40 Lube Oil (from Engine) Cooler, the Cold Fluid is Normal Cooling Water, so the plates always are SS316L Plates.

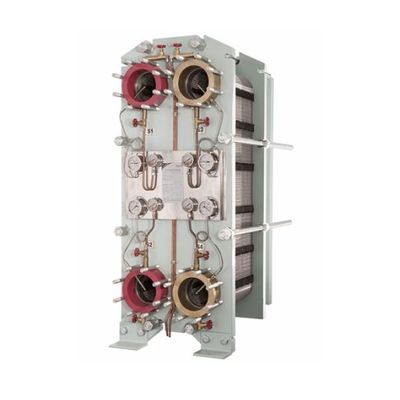

SHINEHEAT - Pre-assembled Plate Heat Exchanger

Shineheat offer a flexible solution for Plate Heat Exchanger in delivery, that`s Pre- assembled Plate Heat Exchanger Solution. Pre-assembled Plate Heat Exchanger is deliveried into two packs, one is Pre-assembled Plates and Gaskets and another is Frame Accessories Pack, which is optional [ and flexible solution toward to Customer in view of following aspects.

Welded Plate and Shell Heat Exchanger

SHINEHEAT - Plate and Shell Heat Exchanger

The plate and shell heat exchanger adopts advantage of plate heat exchanger, meanwhile making up for shortcoming of shell and tube heat exchanger. The oval transfer plate combine with shell distribute the stress evenly to be more suitable for operation under changing temperature. At the same time, to provide compact size, high efficiency, and high temperature resistance and so on.