Shumar Engineering (Pty) Ltd. products

Shumar - Coal Crushers

Shumar Crushers are engineered with dual machined rolls designed to accommodate precise crusher segments, typically featuring six segments per roll. Utilized in both primary and secondary crushing applications, these segments are crafted from manganese steel to ensure durability and effective performance. A unique feature is the spring-loaded loose roll that minimizes shock loads during stalls caused by non-crushable material. This roll can be easily adjusted using spindles to cater for product size variations or wear compensation. The robust design includes spherical roller bearings sealed by a taconite type labyrinth seal, ensuring optimal protection against dust and environmental factors. The drive system employs a V-belt drive and independent geared motors for each roll, contributing to the crusher`s compact structure.

Shumar - Primary and Secondary Coal Scalping Screens

The Odeca Primary Scalping Screen introduces a novel approach to overcoming obstacles faced by traditional screens in handling large-sized materials. Unlike conventional designs, which struggle with materials exceeding 250mm, leading to pegging and damage, the Odeca screen handles inputs as large as 600mm efficiently. It achieves this through a unique combination of inclined screen design and vibrator motors that produce a straight line motion, eliminating the need for drive stands and making the screen virtually maintenance-free. This setup allows for adjustable stroke to suit various materials and sizes. Despite having less open area than many screens, the Odeca maintains high efficiency and throughput, excellently coping with tough South African mining conditions owing to its robust construction. It is offered in single and double deck configurations, along with a specialized primary scalping range.

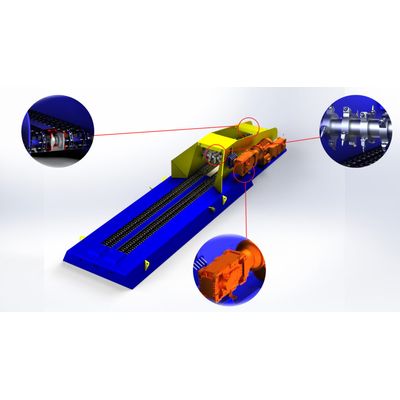

Shumar - Feeder Breaker for Coal Mining

The Shumar Feeder Breaker is a heavy-duty machine designed for efficient material handling in mining and industrial environments. With a capacity of 700 tons per hour, it provides a substantial reduction ratio and is equipped with a long service life, requiring minimal maintenance. Its design allows for a level compact surface and does not necessitate a high wall, enabling operation on flat ground. The feeder breaker features a dual drive system and separate motors, allowing operational continuity even if one chain breaks. The adjustable drum height ensures optimal product sizing, and the machine includes a sizing ramp for picking up smaller materials and hopper side boards. Direct drive breaker and head shafts are part of the machine`s primary configuration, with optional features such as an electric panel, mechanical drives without VSD, and mechanical drives with VSD on both chain drives and the breaker drive, enhancing its versatility and efficiency in various applications.