- Home

- Companies

- Sigma Thermal, Inc.

- Products

Sigma Thermal, Inc. products

Thermal Fluid Heating Systems - Pre-Engineered Thermal Fluid Systems

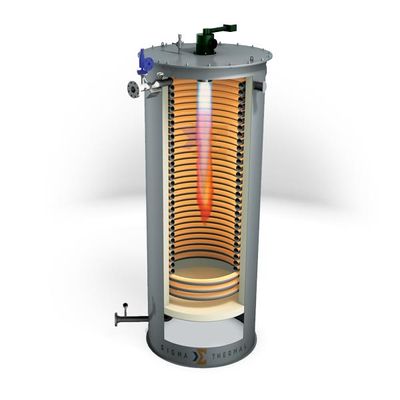

Sigma Thermal - Pre-Engineered HC2 Gas Fired Heaters

The pre-engineered HC2 thermal fluid heater is available in standard sizes from 500,000 to 100 MM BTU/hr. Configuration options include vertical up-fired, vertical down-fired, and horizontal. This system is skid mounted with a burner and integrated control panels. Sigma Thermal also offers custom thermal fluid heater designs for a wide variety of project-specific design challenges.

Sigma Thermal - Pre-Engineered Sigma Hot Oil Transfer System (SHOTS) Electric Process Heaters

Sigma Hot Oil Transfer System (SHOTS) are electrically powered thermal fluid heating systems. SHOTS incorporate an electric circulation heater with a low watt density immersion bundle and fluid circulation pump to create a simple, robust, and reliable system. This system uses electricity to heat your thermal fluid instead of natural gas, fuel oil, or biomass fuel sources. We also offer custom designs to meet specific requirements.

Electric Process Heaters

Sigma Thermal - Circulation Heaters

An electric process circulation heater is used as a conduit to facilitate the flow of process fluid directly over heating elements. Circulation heaters heat a variety of fluids from high-temperature gas to hard to heat liquids. The heating elements, vessel, terminal connections, and mounting structures are packaged for quick installation. Heaters may be installed horizontal, vertical or even sloped for vaporizing liquids.

Sigma Thermal - Electric Immersion Heaters

Electric immersion heaters are typically inserted directly into a pipe, tank, or vessel to heat process gases or liquids. Since the heat is generated by electricity, virtually all of the energy is consumed by the product being heated. As a result, the liquid is heated near 100% efficiency. With standard elements constructed of Alloy 800, these heaters are designed to heat a variety of fluids and maintain corrosion resistance.

Biomass Energy Systems - Biomass-Fired Combustion System

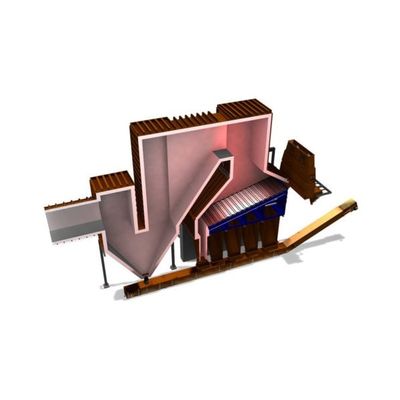

Sigma Thermal - Wet Fuel Furnace

Used largely in the wood products industry, where higher moisture content fuels such as hogged bark and green wood chips are available. The reciprocating grate achieves gasification through the staged combustion of wet fuel. Our grate is divided into multiple sections, allowing for varying speeds and controlled underfire air zones, resulting in the combustion of your fuel in a manner that is considered to be more complete. Depending on the moisture content of the fuel, the grate reacts to obtain the maximum energy amount from the fuel. This prevents the over burning of dry fuel and the underutilization of wetter fuels by altering the amount of time the fuel spends on the grate.

Sigma Thermal - Biomass-Fired Hot Gas Generator

Clean hot gas generation is available for systems requiring direct heat. Rotary dryers for the preparation of material to be used in OSB, MDF, Pelletizing, and others. Maximum combustion control results in fewer issues from sparks and dirty flue gas that are common with other systems.

High-Pressure Steam Generators

Sigma Thermal - High-Pressure Steam Generators

The high-pressure steam generator produces non-toxic process heat. NUK® High-Pressure Steam Generator: The NUK® High-Pressure Steam Generator is a closed-looped (hermetically sealed) system that produces steam for high-temperature applications. Therefore, this steam generator is able to produce non-toxic process heat while offering the same advantages of a conventional hot oil system.

Thermal Fluid Systems

Sigma - Model HC-1 - Thermal Fluid Heaters

The HC-1 thermal fluid heater is available in standard sizes from 1 to 30 MM Btu/hr. Configuration options include vertical up-fired, vertical down-fired, and horizontal. Custom heater designs are also available to meet a wide variety of project-specific design challenges. Sigma Thermal also offers HC-2 thermal fluid heaters, biomass-fired thermal fluid heaters as well as options for electric process circulation heaters.