- Home

- Companies

- Sovema Group S.p.A.

- Products

Sovema Group S.p.A. products

Lithium-Ion and Advanced Batteries - Cell Assembly

Sovema - Pouch Cell Assembly Line Machine

This line is designed for start-up and pilot production of pouch cells, available from manual to fully automatic operation. Designed for start-up and pilot production of pouch cells, with dimensions suitable for EV and Energy Storage applications. The line can be customized to meet each customer`s specific technical requirements, and allow them to develop new cell sizes and test different chemistries with high quality standards. A full range of options allows each customer to choose the most suitable automation level, as well as the quality control options needed to achieve the highest repeatibility and precision results.

Sovema - Cylindrical Cell Assembly Line Machine

This compact line, designed for both research and factory labs, is suitable for the production of a wide range of cylindrical Li-Ion cells, including 18650, 26650, and 21700 formats.

Sovema - Roll to Roll Notching Machine

This equipment is designed to perform lithium-ion electrode high-speed roll-to-roll notching operation. This equipment is designed to perform the roll-to-roll notching operation of lithium-ion electrodes. This machine ensures high notching speed with the high precision and is suitable for application in factories requiring high yield and final product quality.

Lithium-Ion and Advanced Batteries - Cell Finishing

Sovema - Model SMF - Regenerative High Switching Chargers Machine

Regenerative high switching frequency formation technology for Lithium-Ion cells. The combination of Sovel360 with Sovel chargers and testers allows for the accurate management of the battery formation process in any situation. For laboratories and research institutes, Sovel360 can provide sophisticated functions managing several variables simultaneously. Sovel360 brings essential benefits to the dily business such as extreme programming flexibility (flow-chart configuration), real-time formation/testing trend, real-time auto-diagnostics with log file creation (fast service system), highly detailed reports and graphs, trends comparison on all the variables, multiple synoptical view, and remote management.

Lithium-Ion and Advanced Batteries - Testing

Sovema - Model EOL - Li-Ion Module andd Pack End-of-Line Testing System

Li-ion module and pack end-of-line testing system, ensuring product compliance to the most compelling standards. Take a deeper look to End of Line Testing features and applications and find out how performing and efficient it could be for your company. EOL is designed to be part of a fully-robotized structure and can simultaneously manage one or several modules. The bench is equipped with some pins allowing a perfect pallet positioning via an anthropomorphic robot. Once the module is in place, a tailored tray moves the connecting pins toward the module contact surfaces to let the cycle start.

Lead-Acid Batteries - Oxide Production

Sovema - Chainless Lead Oxide Mill

Good oxide means good battery: Sovema ball mill ensures quality, energy efficiency, and real-time data traceability.

Sovema - Lead Cylinder Casting Machine

Designed to produce pure lead cylindrical shapes for the Oxide Ball Mill, with high control of size and weight.

Lead-Acid Batteries - Grid Making

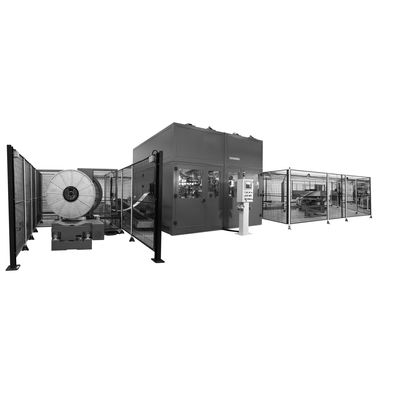

Sovema - Wide Strip Casting and Rolling Lines Machine

The perfect solution to meet the quality and production needs of the most demanding battery manufacturers. The laser system can work in a loop with the finishing rolling mill for continuous strip thickness control, with a precision of 1.5 µm. This option can be installed as a retrofit on all existing machines. The system can work in a loop with the finishing Rolling Mill to guarantee high product quality and significant lead savings in the continuous production process.

Sovema - Model PunchPlus - High-Speed Punched Grids Production Machine

Sovema PunchPlus provides high-speed punched grids production through a continuous lubricant-free strip flowing process. An exclusive plus of Sovema Punchplus is the oil-free operation: thanks to the extremely high punching speed, no lubricant is needed on the grids. Therefore, the machine ensures the unique advantage of obtaining a clean grid without installing cleaning devices downstream.