- Home

- Companies

- STELA Laxhuber GmbH

- Products

STELA Laxhuber GmbH products

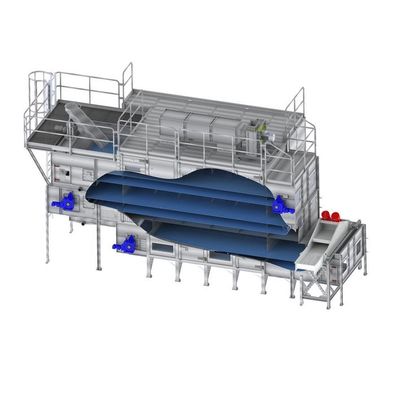

Belt Dryer

Stela - Belt Dryer

At the top, ambient air is fed through heating coils in the fresh air intake and thus heated. Depending on the local conditions, thermal oil, saturated steam, waste heat from combined heat and power and ORC processes or already heated process air can be used flexibly as heating media. By several dryer zones arranged in a row at this upper level it is possible to create drying areas with different process temperatures.

Stela - Belt Dryer

Efficient air distribution due to direct-coupled and frequency-controller multi-vent radial fans. Modular plant system that can be easily expanded. Low heat and electricity consumption thanks to perfectly coordinated components. Compact design. Optimum product distribution thanks to double spreader screws. Product-turning device for an even, final moisture content and energy-efficient product ventilation. Top-down ventilation. Available in 2m and 3m belt widths.

Stela - Belt Dryer

Reduction in quantity of exhaust air. Reduction in emission mass flows. Reduction in specific thermal energy consumption. Large access points for easy maintenance and cleaning. Enclosed design allows it to be set up externally in temperatures down to -40°C (insulated dryer body). Optimum product distribution thanks to double spreader screws. Product-turning device for an even, final moisture content and energy-efficient product ventilation. Top-down ventilation.

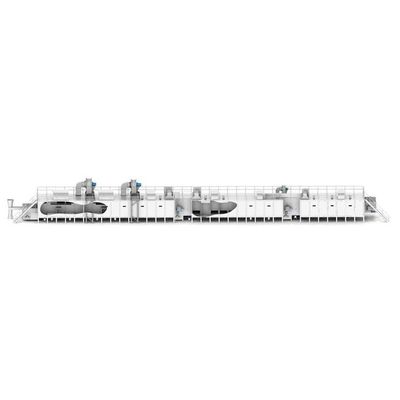

Layer Dryer

Stela - Layer Belt Dryer

The belt dryer type BTF-L is a layer dryer for food and pet food applications. Layer dryers combine several belts on top of each other in one dryer housing.

Stela - Layer Belt Dryer

The belt dryer type BTF – S is an efficient stage dryer, which was specially designed for use in the food and pet food sectors. Stage dryers are characterised by the arrangement of several belts (stages) one behind the other.

AgroDry - Stela Stationary Dryers

Stela AgroDry - Stationary Dryer with Biturbo System

AgroDry grain dryers with Biturbo system are modular and can be realized in all capacities from approx. 7.5 t/h upwards. The basic functionality always remains quite similar: a free-flowing drying product, for example different types of grain, is conveyed into a storage bunker. From there, the drying product passes through the drying system from top to bottom by gravity only.

Mobile Agricultural Dryer

Stela - Universal Mobile Continuous Dryer

The Universal type drying system is a roof dryer that works by the suction system. The system is filled via the large filling hopper and powerful elevator. From the storage tank, the product falls by gravity through the drying and cooling elements, through which roof-shaped ducts run. The hot air created in the air heater is fed into the product through the hot air roofs. During drying, the goods release their moisture to the drying air. The air saturated with moisture escapes through the exhaust air roofs. The heated exhaust air from the cool zone is mixed with the hot air flow to recover the heat.