Sulfur Recovery Engineering Inc services

Design Consultation Services

SRE’s extensive knowledge base makes us a trusted source in terms of identifying your processing requirements and restrictions, if any. Our expert consultation offerings focus on, but are not limited to, the following: SRU Capacity and De-bottlenecking Studies for future upgrades or retrofit planning in advance of scheduled turnarounds, Complete in-house SRU Engineering Design services, Design review in conjunction with best practices, SRU and Amine Unit performance predictions with modelling, Post-Construction Management involving pre-commissioning, commissioning, start-up services, Performance Guarantee Verification to validate your investment

SRE Simulation Services

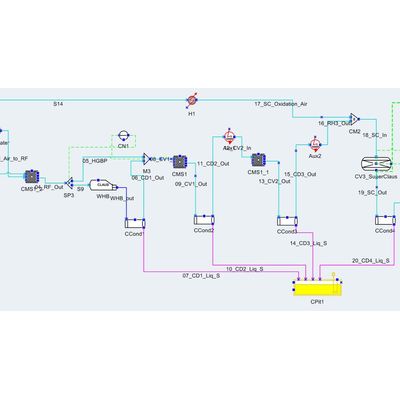

Sulfur Recovery Engineering (SRE) has partnered with Virtual Materials Group (VMG), allowing SRE to use the powerful VMG Sulfur Plant simulation software in-field (VMGSim). Using over 20 years of accumulated SRE sulfur unit data, our team is able to accurately model any given SRU. In conjunction with our field results, the models provide important process values such as Reaction Furnace adiabatic temperature, Converter bed dewpoints, and catalyst activity providing the most up-to-date and accurate performance correlations all within the most flexible SRU modeling tool. Our field testing engineers use VMGSim to model each plant that we visit and have found it to be a powerful tool for on-site unit optimization. Our engineering reports also include a ‘tuned’ model of the client’s SRU such that they themselves can open and manipulate the variables to track operational trends in their plants. A great tool!

SRE Learning Services

SRE offers on-site Sulfur Recovery Unit (SRU), Amine Unit, and Simulation Training for Operators, Engineers, and Management teams. These seminars are tailored to your specific plant, will address your operating concerns, and are designed to maximize value with respect to your time and budget constraints.