Suzhou SC Solar Equipment Co., Ltd products

PV Module Manufacturing Automation Turnkey Solution

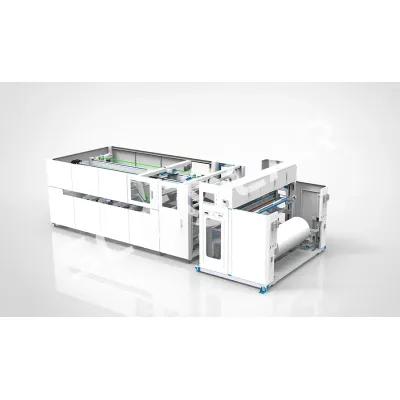

SC-Solar - Intelligent Edge-Finding Eva/Poe Cutting & Layup Machine

SC SOLAR provides a comprehensive automation solution for PV module manufacturing, emphasizing precision and efficiency. The solution includes intelligent edge-finding technology for cutting and laying encapsulation films and backsheet materials, featuring automatic deviation correction to enhance product accuracy. Its non-stop hot-melt roll change capability and swift 12-second cycle time significantly boost manufacturing throughput. It supports various module sizes with a simple one-click switch, aligning with different production requirements. Complementary machines, such as the EVA floating and pre-melting machine, auto bussing, and laminators, seamlessly integrate to create an efficient production line. The system also encompasses sophisticated welding and framing technologies and advanced solutions for finishing processes like labeling and palletizing. With a focus on enhancing stability and operational efficiency, SC SOLAR positions itself as a leader in intelligent equipment for the solar industry.

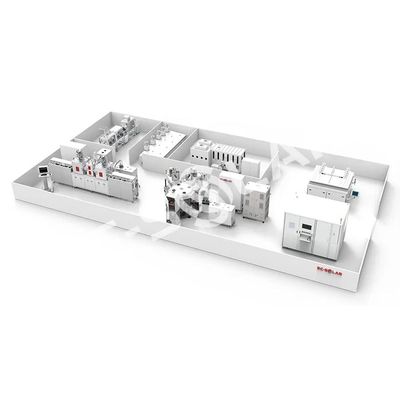

PV Cell Manufacturing Automation Solution - Perovskite Equipment

SC-Solar - Perovskite & Tandem Solar Cell Experimental Line

SC SOLAR specializes in providing cutting-edge automation equipment for the manufacturing of photovoltaic (PV) cells, focusing on perovskite and tandem solar cell technologies. Their product lineup includes specialized machinery such as the Perovskite Cell Glass Cleaning Equipment and various deposition systems like the Vertical PVD System with U Turn for efficient film application. The company also offers highly specialized equipment like the Multi-source Co-evaporation Dry Process Perovskite Cluster Evaporator, designed for complex layered deposition processes. In addition, SC SOLAR provides solutions like the Automatic Packaging Line for Perovskite Solar Modules and various coating and welding machines to streamline solar module assembly. As pioneers in solar industry intelligent equipment, SC SOLAR's technology ensures high efficiency and precision, catering to the increasing demands of the renewable energy market.

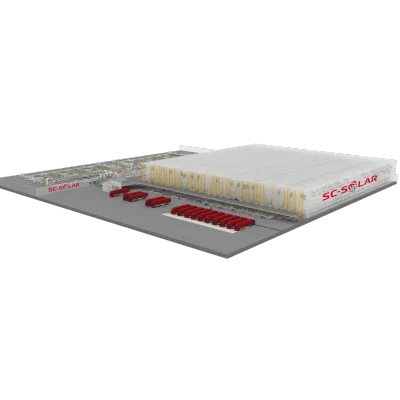

Packaging Line and Stereoscopic Warehouse System

SC-Solar - Packaging Line and Stereoscopic Warehouse System for Solar Module Handling

SC SOLAR offers an advanced Packaging Line and Stereoscopic Warehouse System tailored for the handling and storage of solar modules. The packaging line includes various machines such as pallet loaders, scanning and fastening machines, as well as flipping and stacking devices, which are designed to efficiently handle different solar module sizes. The system supports both regular and dual-glass modules with maximum pallet dimensions of 2580x1150x1320 mm. It is capable of managing module weights up to 1500 kg per pallet and operates at a cycle time of ≤120 seconds per pallet. The line supports horizontal and vertical pallet packaging cycles and facilitates handling from sorting to packaging using Automated Guided Vehicles (AGVs). The stereoscopic warehouse system enhances storage density, operational efficiency, and inventory management while reducing labor costs and improving safety. It offers a substantial storage capacity of 39,988 units.

Intelligent Logistics System

SC-Solar - Intelligent Logistics Stacking for Photovoltaics

The Intelligent Logistics Stacking AGV is a sophisticated automated guided vehicle designed to optimize material handling in the photovoltaic sector. Featuring 3D natural navigation, this AGV provides exceptional environmental adaptability, enhancing operational efficiency and safety as it replaces traditional forklifts. With an impressive load capacity of up to 1000kg and a lifting height reaching 1.6 meters, it is well-suited for heavy-duty tasks. Equipped with a radar-based visual system, it achieves a remarkable positioning accuracy of 10mm. Its integrated dispatch system enhances logistical operations by interfacing seamlessly with ERP systems, ensuring optimal path calculations and ultra-efficient performance. The omnidirectional radar further enables superior adaptability without the need for infrastructure modifications. This system represents a significant leap in intelligent equipment technology for the solar industry.