TEMA Process B.V. products

Fluid Bed Dryers - Fluid Bed Dryers

TEMA - Fluid Bed Dryers & Coolers System

How does a fluid bed dryer work? A continuous fluid-bed system is a machine in which a continuous flow of “wet” powder, granular or flakes material is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate. The wet solids are lifted from the bottom and causes the solids to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized. Conveying of the product is achieved by means of a low-frequency, high amplitude shaker mechanism. The “Shaking” motion plug flow of the Tema fluid bed, allows first-in, first-out drying of products and well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time.

TEMA - Fluidized Bed Technology for Thermal Processing

A fluid bed is an effective unit to thermally treat powders, crystalline products, pelletized or extruded materials. High heat and mass transfer are obtained as a result of the intimate contact between fluidizing air and product.

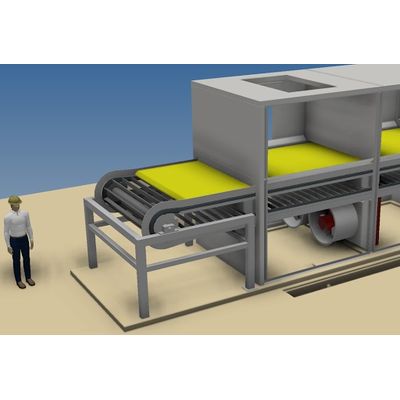

Tema - Shaking Fluid Bed Dryer

Shaking fluid bed units for continuous operation and suitable for sticky materials with a wide particle size distribution. The shaking motion improves the fluidization and transport of any material within the fluid bed. Drying gas temperature up to 750 °C and product temperatures up to 400 °C are achieved.

TEMA - Static Fluid Bed with Submerged Heat Exchangers

Static fluid bed units in continuous and batch type for more uniform materials that do not tend to agglomerate. It is possible to install submerged heat exchangers in a deep static bed. With submerged heat exchangers energy input is both from the fluidizing air as well as from the heat exchangers reducing the size of the equipment and limiting the exhaust air volume.

Fluid Bed Dryers

TEMA - Belt Dryers & Coolers

How does a belt dryer work? A continuous conveyor belt dryer system is a particularly gentle thermal treatment for your product. It can dry large quantities with high moisture loads, temperature sensitive or brittle products and products which require a long residence time. The dryer is divided into segments (drying zones) in order to create high air velocities with a lower air volume. Fans and heaters can be placed inline or outside the tunnel and will heat up the saturated and cooled air again. This allows the use of low temperature heating media and a smaller total airflow which is repeatedly heated up. The wet solids are continuously and evenly divided onto a perforated conveyor belt, this can be a single or multiple belt system.