- Home

- Companies

- Trasfor S.A.

- Products

Trasfor S.A. products

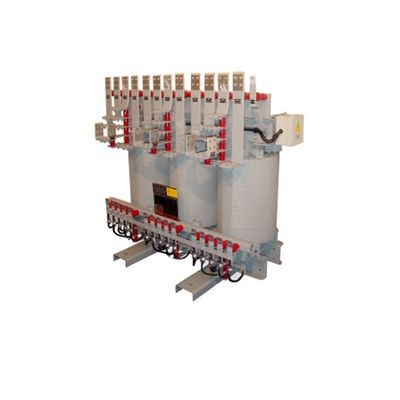

Trasfor - Cast Resin Transformers

The product is suitable for use with medium voltages, power ratings up to 25/30 MVA and insulation voltage up to 52 kV. The windings are made with various shapes of aluminum or copper conductor. Each manufacturing stage of the cast coils passes through automated process controls that enable a product with a uniform quality that tolerates the most severe thermal and mechanical stresses. The use of “Step Lap” mitred cores enables losses to be significantly reduced, increases the efficiency of the transformer and guarantees low noise levels.

Trasfor - VPI Transformers

This is a solution used to produce low voltage (less than 1.1 kV) and medium voltage (less than or equal to 24kV) coils. The windings in copper or aluminum can have different types of insulating materials, depending on the the various applications. Transformer power can reach 20-30 MVA. Customised solutions are available for any kind of transformers. Coils or complete products are furthermore protected by immersion in a bath of epoxy resin inside pressurized vacuum vessels (VPI process).

Trasfor - VPI Iron Cored and Air Cored Reactors

Chokes and reactors always need to be calculated, designed and built specifically for each application. There are almost no standard products in this field.Trasfor is able to optimally solve all operational requirements thanks to the experience of its own engineers, an extensive database of applications and specialized proprietary software used for the calculations. The choice of materials used, however, will vary depending on the ultimate purpose of the component and the type of performance and technology to be applied.

Trasfor - Transformers and Reactors for Rolling Stock

The IRIS standard, the latest to regulate applications in the rail sector, sets out very strict standards for usage in this field. This type of application is characterized by the aggressive environmental conditions, a restrictive MTBF rate (Mean Time Between Failures), the practical exclusion of maintenance and repetitive electro-mechanical stress. In addition, there is the safety aspect regarding the installation position of the units. A positioning that needs to satisfy the required mechanical behavior during freezing, shocks and vibration, and demands the employment of highly competent specialists. Simulations with FEA tools in order to predict the behaviour of the components against shock, vibrations and fatigue stresses are used.

Trasfor - Transformers and Reactors with Liquid Cooling

This technical solution is particularly suitable for applications involving high currents or where space is limited. The conductor may be cooled internally with a liquid refrigerant (direct cooling) or simply placed next to dissipating surfaces where the liquid is made to circulate (indirect cooling). This type of cooling system allows heat to be dissipated away from the points of installation and has the advantage of providing compact solutions in protected enclosures, despite the high concentration of power involved.