- Home

- Companies

- Valtech Corporation

- Products

Valtech Corporation products

Molded Polymer for Electronics Sector

Valtron - Ingot Slicing Beams for Semiconductor Wafering Processes

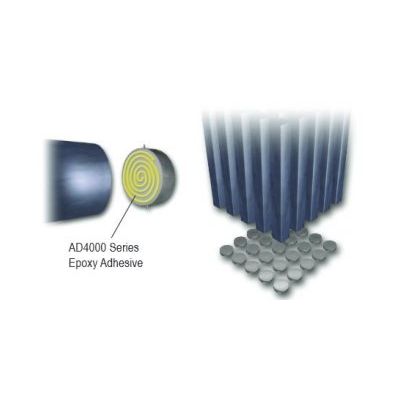

Valtech manufactures ingot slicing beams for use in fixturing various semiconductor materials in preparation for the wafering process. These substrates can be fully customized to accomodate various ingot diameter and lengths as well as custom designed to meet specific user requirements. The ingot slicing beams are available in a variety of material formulations allowing use in multiple wafering processes including slurry wire slicing, diamond wire slicing and ID saw slicing. The unique surface conditions of these slicing beams have a high affinity for epoxy adhesives and prevent epoxy residue from remaining on sliced wafers in post slice demounting and cleaning applications.

Valtron - Photovoltaic Slicing Beam

The VALTRON Photovoltaic Slicing Beam is made of a unique composite polymer proven to be very effective with wire saw slicing equipment for photovoltaic wafer processing. The substrate materials are electrically insulating and can be mounted directly to wire saw mounting fixtures, eliminating the need for glass and other substrates. The unique surface characteristics promote improved adhesive bonding with improved dimensional stability compared to conventional graphite and glass products. The beams are available in various sizes to accommodate photovoltaic ingots as large as 200 mm.

Valtron - Semiconductor Wafering

Valtech has supplied VALTRON® temporary bonding adhesive systems, ingot support beams, and formulated detergents for the semiconductor wafer process for nearly 20 years. These products have evolved along with the technology as it has transitioned from annular (ID) slicing to multi-wire saw slicing. Our commitment to meeting our customer’s requirements as technology changes has allowed us to continue to develop new and innovative solutions for the semiconductor market. Although the general processing of semiconductor wafers is considered to be consistent throughout the industry, we realize that each customer has specific requirements that call for unique solutions. Our extensive technical expertise and ability to work closely with our customers allows us to provide these solutions.

Valtron - Epoxy Adhesives for LED Wafer Slicing

Light Emitting Diodes (LED) offer many advantages over incandescent light sources, such as lower energy consumption, longer lifetime, smaller size, low heat generation, greater durability and reliability. Valtech is on the forefront of this high-growth industry supplying a complete line of VALTRON® epoxy adhesives, molded polymer slicing beams and formulated detergents for the manufacture of LEDs. The VALTRON line of products offer enhanced performance characteristics that improve manufacturing yields for the process of slicing silicon carbide, sapphire, silicon, and gallium arsenide into wafers that are eventually made into small LEDs. Backed by Valtech`s expert Technical Service and Research & Development support, our customers can be assured that our products will meet and exceed their expectations.

Valtron - Silicon PV Wafer Technology

Building on our experience in the semiconductor industry, Valtech has developed the VALTRON line of adhesives, ingot support beams and formulated detergents to accommodate the unique challenges of the solar wafering process. The rapidly changing technology of solar wafering requires continual development to meet these challenges. Our product development efforts have led to unique products including water resistant adhesive systems for wafering, simple heat release adhesives for monocrystalline ingot squaring, support beam technology compatible with fixed abrasive wire slicing, and multiple new detergent formulations to accommodate the in-line wafer cleaning processes. We continue to work closely with our customers to understand and meet their continually changing needs in this dynamic industry.