Winergy - Flender International GmbH products

Hybrid Drive

Winergy - Hybrid Drive for Wind Turbines

The HybridDrive is Winergy`s response to the challenge of further reducing the costs of energy generation. With the direct connection of a three-stage planetary gearbox and a permanent-magnet synchronous generator, a medium-speed drive has been designed ensuring the high efficiency. Both Winergy‘s mechanical and electrical engineering expertise are reflected in the HybridDrive.

Gearbox

Winergy - High Density Gearbox

Our gearbox concept High Density unites power density, reliability and efficiency on a new level. The concept set new market standards by increasing torque density by more than 25 percent up to 200 Nm/kg while relying on our proven gearbox design.

Winergy - High Speed Gearbox

Our gearbox concept High Density unites power density, reliability and efficiency on a new level. The concept set new market standards by increasing torque density by more than 25 percent up to 200 Nm/kg while relying on our proven gearbox design.

Winergy - Medium Speed Gearbox

Our gearbox concept High Density unites power density, reliability and efficiency on a new level. The concept set new market standards by increasing torque density by more than 25 percent up to 200 Nm/kg while relying on our proven gearbox design.

Generators

Winergy - Squirrel-Cage Induction Generator

Our squirrel-cage induction generators are durable, reliable, and easy to maintain. Due to a simple mechanical and electrical design without brushes and slip rings, they are extremely compact and lightweight despite their high performance. The construction and the technical design of the generator therefore have exactly the characteristics that are required in wind power industry.

Winergy - Double-Fed Induction Generator

The double-fed asynchronous generators have proven themselves thousands of times over worldwide. A rotor fed by the converter is used for speed control. Together, the generator and converter meet all current grid codes. Due to the small size of the rotor converter and the converter losses from the rotor circuit, the system features a high efficiency and low investment costs.

Winergy - Permanent-Magnet Synchronous Generators

Thousands of times in operation worldwide. Synchronous generators using permanent magnet technology are common in the wind industry. The full converter concept offers advantages, such as optimized yield because of the wide speed control range. This is complemented by the benefits of the permanent magnet technology. These include low maintenance and reliability, as no electrical excitation equipment is required. They bear a high efficiency and ultimately ensure a high total energy yield.

Direct Drive

Winergy - Gearless Direct Drive Wind Generator

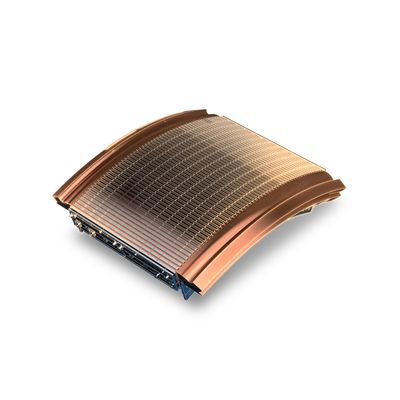

The gearless Direct Drive wind generator is a multi-pole synchronous machine, usually equipped with permanent magnet technology. Winergy offers you custom-made stators in segmented design for your Direct Drive wind generator. Based on its modular platform concept, the generator`s stator is not manufactured as a whole but is composed of preassembled sub-segments. This offers especially advantages for the transport and erection and allows a customized adaptation to the respective performance requirements. The stator segments are integrated optimally into the drive train of the wind turbine using finite element calculations.

Wind Coupling

ARPEX - Wind Coupling for Wind Turbine

ARPEX ARV wind couplings are used in the drive train between the gear unit and generator to transmit torque and to compensate for misalignment. In the series supply are couplings up to a power of 6MW. The compact design allows radial assembly and disassembly without displacement of the gear unit or generator. The stainless plate packs with optimized shape, which were specially developed for the application in wind turbines, ensure a high torque transmission combined with large misalignment values with extremely low restoring forces as well as maximum service life.

ARPEX - Wind Coupling for Wind Turbine

The ARPEX GIGA is a powerful solution for wind turbines and integrated drive trains. It is a maintenance- and wear-free, double-joint disc coupling. Located between the rotor shaft and gear unit, the coupling protects the gear unit and drive train against bending and thrust loads from the rotor – thus significantly increasing the lifetime of bearings and gears. The coupling can transmit torques of up to 12,000,000 Nm and compensate axial, angular and radial misalignments. The ARPEX GIGA can be integrated in all wind turbine concepts (low, middle or high-speed applications). Optionally, it can be delivered as a single-joint coupling.