- Home

- Companies

- Winno Energy Oy

- Products

Winno Energy Oy products

Micro Chp Plants

We can use waste wood with higher moisture content up to 40% (Our plants do not need a dryers before gasification), Waste wood can be low-quality waste wood = lower fuel cost to produce electricity, Our gas cleaning system is water based cleaning system = cleaner gas and lower OPEX costs when engine gets clean gas, Our pricing is competitive with around three year payback time, Delivery will be on the CHP island which is platform mounted plug&play solution, Remote locations will get quickly required extra power capacity without expensive grid extensions, Reduces carbon footprint when waste wood can be used as valuable source, We have got testing facilities available and we are happy to test any new kind of fuels.

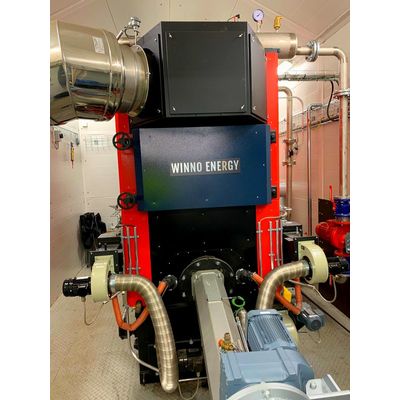

Wid Compliant Waste Wood Biomass and Rdf Combustion Plants

We have got WID compliant boilers for the C grade waste wood and SRF combustion: Our WID compliant waste wood gasification boiler manufacturer has over 60-years experience, Works with really low-quality wood, MDF, and chipboard based biomass, and waste wood, SRF combustion is possible together with biomass (80/20% ratio), Waste wood combustion is more than two seconds 850-degree gasification combustion process. (This is important because grate firing struggles to meet two seconds 850-degree combustion), Boiler power range: 8%-100% (During summer months boiler can run nicely with low heat demand and it accelerates nicely when the boiler is already running), If there are power cuts boiler can start itself automatically, Ash handling is wet ash handling and made from acid resting steel, Flue gas dust content within the boiler is only circa 50 mg/nm3, keeping the boiler clean, The boiler needs to be cleaned only once a year as part of its annual maintenance.

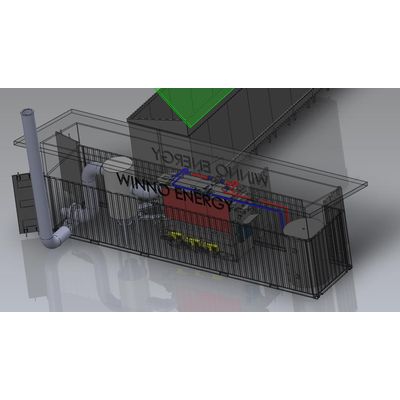

Winnovative Biomass Boiler Island Solutions

Best solution for commercial biomass projects (0.2-1MW) We are offering boiler island solutions for our our who are switching to the biomass heating. Using our Winnovative biomass solutions they can reduce project risk and speed up delivery on site when our boiler island is installed under our supervision. Combined Heat and Power option: Our boiler island solution allows CHP units which produce electricity via ORC (Organic Rankine Cycle) technology. We have selected an ORC partners for biomass projects who have a proven track record.

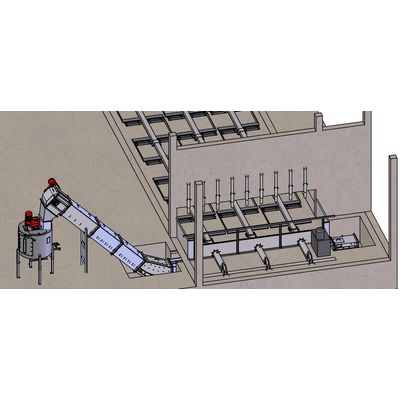

Biomass Boilers, Walking Floors and Components

Great biomass boilers and walking floor storage solutions for the installers who want to build their own biomass boiler plants from components! Our biomass boilers are used for heating of large sized residential and industrial premises and supplying heat for technological needs. We can offer following boilers and biomass heating components for your biomass projects: Biomass Boilers, Walking floor solutions for biomass fuel storage, Spring agitators for biomass storage, Small biomass fuel storage silos up to 35m3, Multi cyclones for flue gas cleaning, Fluegas fans, Feeding augers with automation, Scraper biomass conveyors. Fuel used: saw dust, wood chips, pellets of various types, compressed peat, grain waste, grain or other biomass based fuels.