WS Wärmeprozesstechnik GmbH products

REKUMAT

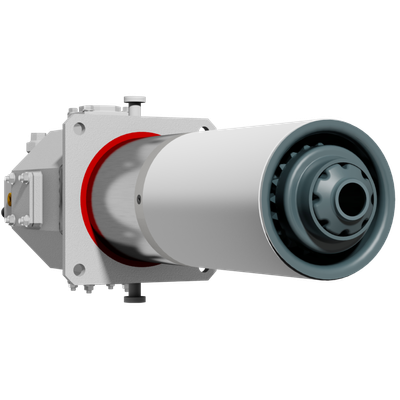

FLOX REKUMAT - Model C - Burner

The FLOX® burner series REKUMAT® C is characterized by an integrated ceramic high-performance heat exchanger. Thus, operating temperatures of up to 1,300 °C are possible. Minimal thermal wear due to FLOX® combustion technology, as well as decades of experience make the Rekumat® C one of the most successful self recuperative burners globally. The REKUMAT® C burner series is Green Gas Ready.

REGEMAT

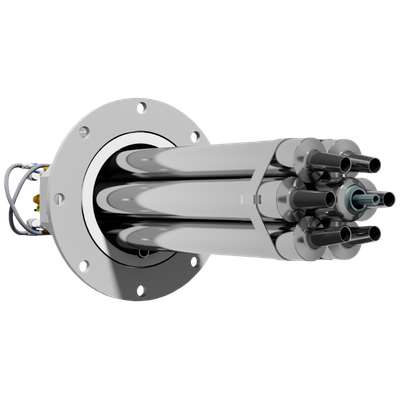

FLOX REGEMAT - Model 250 - Burner

The REGEMAT® 250 revolutionized the world of continuous galvanizing lines shortly after its introduction. With unprecedented efficiency and NOx emissions that make downstream exhaust gas treatment unnecessary even under the strictest regulations. Even today, customers who rely on the REGEMAT® 250 are optimally equipped for all possible future developments. Especially since the burner has all 'Green Gas Ready' criteria with flying colors. Thanks to their use in recirculating double P-tubes, these systems are ideally prepared for the future of alternative fuels such as operation with green hydrogen. With well over 10 years of operating experience of thousands of burners, the REGEMAT® 250 is now proven reference technology for all customers who want a particularly future-proof and highly efficient system.

Other Products

FLOX - "FLameless OXidation Technology

The original with over 30 years of experience: Fire without flame. Fire without flame - sounds paradoxical and is at the same time a groundbreaking discovery. This combustion principle, which finds a wide range of applications in numerous variants, especially in the steel industry and in burners for heat treatment, has unbeatable advantages. Unlike conventional burners, the sophisticated mixing of fuel gas, combustion air and recirculating exhaust gas in WS burners in FLOX® operation avoids peaks in combustion temperature. Thus, despite the application of high air preheating rates to significantly increase efficiency, the simultaneous increase in NOx emissions can be avoided. In addition, the homogeneous temperature distribution in the kiln ensures high-quality products as well as significantly reduced burner wear. All important factors for environmentally oriented thinking, economic action and the manufacture of high-quality products. However, the potential of FLOX® technology is far from exhausted. In various national and international projects - partly supported by corresponding subsidies - the focus is on future fields of heat process and energy technology. For years, we have been focusing in particular on adapting our burners to the special requirements of green fuels such as hydrogen, ammonia or methanol.

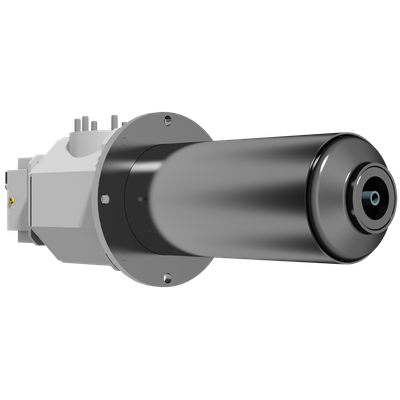

FLOX LUVOMAT - Burner

Low-NOx with pre-heated air. The LUVOMAT® can also be used if externally preheated air is already available but the FLOX® combustion process is still to be used. This can be the case, for example, if the furnace atmosphere does not permit operation of recuperator or regenerative burners, such as in substoichiometric operation or dusty and aggressive furnace atmospheres. So far, LUVOMAT® burners have been realized up to a thermal output of about 1 MW, but higher outputs are possible in principle. The requirements for LUVOMAT® burners are very different due to often externally specified boundary conditions. A detailed burner design is therefore always carried out in close coordination with the customer.