Yingkou Jinchen Machinery Co., Ltd. products

High-efficiency Solar Cell Equipment & Solution

Jinchen - High-efficiency Solar Cell Tube PECVD Solutions

Jinchen tube PECVD solution realized the preparation of the core material of TOPCon solar cell --- "Silicon oxide + in-situ doped amorphous silicon" , meanwhile, it won great breakthrough on several core technologies, such as suppressing explosion of amorphous silicon, preventing conduction of electric field and realizing the whole process of high-efficiency solar cell , etc.

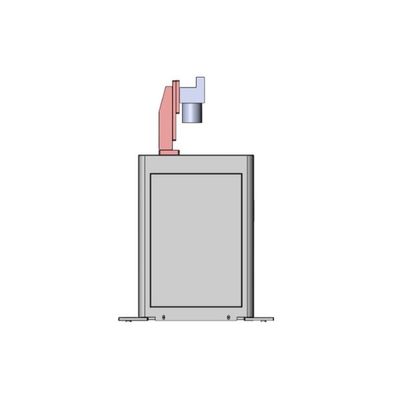

Jinchen - Solar Cell Injection Machine

Maximum stack number is 260 (lessthen 300) to ensure better temperature control process. Blow compressed air from all sides to improve temperature control uniformity. Single cell Bypass(not entering into stack during process shielding to avoid debris risk). Soft contact during electrified contact, motor driven (non-cylinder). Integrated PL module with NG discharging function. With loading buffer function when unloading (supply material for sorter machine). Automatic backflow of the upper and lower cover plates. Fully integrated scheme, strong adaptability to photoelectric transformation (4.5m,6.5m,9.5m,11m).

Jinchen - AOI Testing Equipment for Solar Cell

Judge kinds of cell defects, such as fragments, broken edges, dirt, printing defects, etc., and timely alarm when appearing batches of defective cells. Use multiple light sources to take photos, the defect detection rate is higher and the definition is higher.

High-efficiency Solar Module Equipment & Solution

Jinchen - Automatic Taping Machine

Vacuum adsorption, adhesive surface without contacting with tapes to effectively avoid imprint residue, cleaning, leakage and other problems. Pneumatic rotary joint with independent patent, with small Air consumption, simple and stable operation. Can choose different paste directions within the same module: Horizontal or vertical . 30 tape points, working cycle time ≤ 20S.

Jinchen - PV module Automatic Fitting Paper Corner Protector

Good consistency, Firm and hard to loose or drop out. Compatible with various corner protector in different dimensions and materials. Packaging cycle time: 20s/module. Save 2 labors/shift.