How to Enhance Combustion with NIR-Bs to Reduce Emissions and Boost Energy Efficiency

In the realm of furnace thermal imaging, utilising NIR-B-2K and IMAGEPro Glass serves as an excellent starting point to minimise energy consumption, reduce emissions, and optimise combustion in fired glass furnaces.

NIR-B serves as the cornerstone for enhancing the optical thermal profile of furnaces, replacing traditional handheld pyrometers like the Cyclops C100L. Key considerations for an effective Optical Profile include:

• Use a calibrated instrument ideally.

• Determine the appropriate emissivity using B&F Manager.

• Emissivity values between 0.93-1.0 are recommended.

• Define repeatable target points.

• Timing is crucial; wait until the flame has extinguished.

• Consider fixing NIR-B in a specific location to strengthen the optical profile.

To improve energy efficiency and reduce emissions, consider the following steps in furnace operations, leveraging thermal imaging NIR-B for optimisation:

Seal the furnace from cold air ingress:

• Repair non-design holes, such as rat-holes or metal line.

• Utilize air or water-cooled burner sealing plates.

• Ensure air-sealed furnace peep sites.

Control excess air:

• Calibrate air and fuel flow-meters.

• Conduct manual tests with hand-held %O2 min.

Low NOx burners:

• Implement oxygen trim using zirconia-based probes.

• Prioritise Steps 1 and 2 alongside combustion optimisation.

Non-combustion strategies:

• Explore alternative raw batch materials and cullet.

• Optimize refractory materials and insulation.

• Consider E-boost, bubbling, personnel training, and BOP.

Additional strategies for primary furnace reduction involve staged combustion, improved control through CFD model-based predictive control, and advanced thermal imaging with NIR-B and IMAGEPro glass.

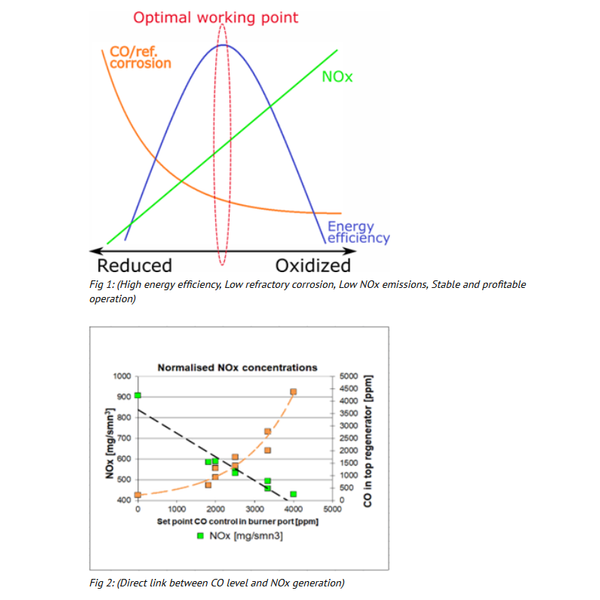

Achieving combustion optimisation raises questions about finding the optimal working point for the furnace concerning energy efficiency and emissions. Assess your control of the combustion process for high energy efficiency, low refractory corrosion, low NOx emissions, and stable, profitable operation.

CO serves as a reliable indicator for the completeness of the combustion process, with a direct link between CO levels and NOx generation. Excess O2 correlation with CO, measured using tools like Lancom 4 portable gas analysers, provides valuable insights for optimising energy balance.

The impact of excess O2 on CO, measured on target walls, combined with NIR-B analysis, allows for peak flames optimisation and energy balance. Critical measurements include:

0.5-1.5% O2 < 200ppm CO: Looks promising.

0-1.0% O2 > 1000ppm CO: Potentially dangerous, suggests furnace reduction.

3% O2 < 200ppm CO: Ratio too high.

3% O2 > 1000ppm CO: Indicates short-circuiting flames.

The next step involves CO2 measurement as part of the operational and decarbonisation strategy using tools like Lancom 4. Key considerations include furnace surveys, identifying air leakage, and understanding the impact of varying natural gas composition, biogas, and H2 blends on carbon credits.

Effective decarbonisation planning starts with knowing your current status. In-furnace thermal imaging surveys, combining NIR-B and Lancom gas analysers, facilitate furnace audits and operational improvements, demonstrating value.

Implementing NIR-B and IMAGEPro for flame performance and optimisation involves steps like recording full firing cycles, analysing high-temperature isotherms for intermittent flame impacts, and assessing reversal points for refractory and air ingress risks.

Improving energy efficiency in glass or steel reheat furnaces becomes achievable through various strategies, with NIR-B playing a crucial role in the decarbonisation of fired furnaces. In the industrial context, the hybridisation of furnaces with technologies like oxygas and electrical furnaces emerges.

As a viable solution for enhancing productivity, energy efficiency, and environmental performance, especially in high-temperature furnaces.