- Home

- Companies

- Environmental Combustion Technologies ...

- News

- The importance of the right refractory ...

The importance of the right refractory material within Incinerators

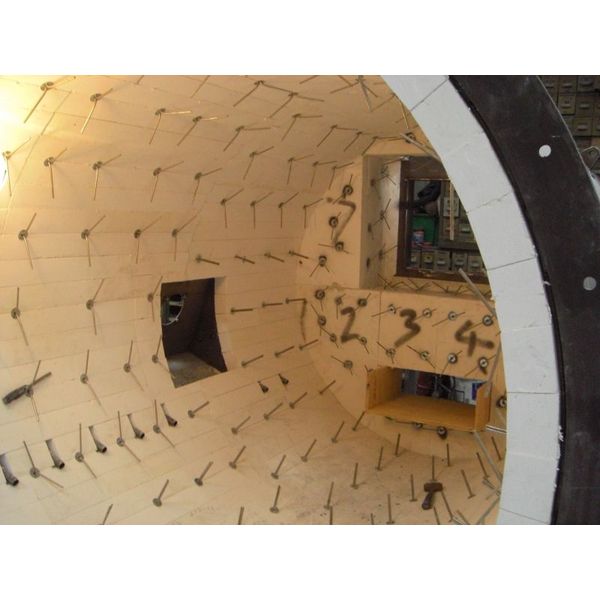

When it comes to designing and operating #incinerators, one crucial factor that is often overlooked is the choice of #refractory #materials. Refractories play a critical role in the #performance and #efficiency of incinerators, as they are responsible for containing high temperatures and withstanding corrosive environments. Selecting the right refractory materials can significantly impact the #longevity, #cost-effectiveness, and #environmental #compliance of incinerators.

Refractory materials perform a vital role in incinerators by providing thermal insulation and containment of high temperatures generated during the combustion process. They act as a protective barrier, preventing heat loss, and ensuring the efficiency of the incineration process.

It is essential to consider the specific requirements of the incineration system, such as the operating temperature, the type of #waste being burned, and the corrosive nature of the #combustion by-products.

By selecting appropriate refractory materials, incinerator operators can optimise the #performance of their systems, improve energy efficiency, and reduce maintenance costs. Furthermore, the right refractories can contribute to environmental compliance by preventing the release of harmful emissions and minimising air #pollution. Another important factor is the type of waste being burned.

Different types of waste can have varying chemical compositions and corrosive properties. Additionally, the thermal conductivity of the refractory material should be considered. Low thermal conductivity is desirable as it helps to minimise heat loss and improve energy efficiency.

The physical and mechanical properties of the refractory material, such as strength, density, and resistance to thermal shock, also play a significant role. These properties influence the lifespan and #maintenance requirements of the incinerator.

Regular #inspections and #maintenance is also vital to ensure the longevity of refractory materials. This includes routine checks for cracks, corrosion, and erosion, as well as timely repairs and replacements when necessary.

Furthermore, it is essential to work closely with the manufacturer who have expertise in incineration applications. Their knowledge and experience can provide valuable guidance in selecting the most suitable refractory materials and offering maintenance recommendations.