- Home

- Companies

- Huayin company

- News

- What factors will influence the oil ...

What factors will influence the oil output of pyrolysis machine?

Several key factors significantly influence the oil output of a pyrolysis machine, which converts organic materials like plastic, rubber, or biomass into fuel oil through thermal decomposition.

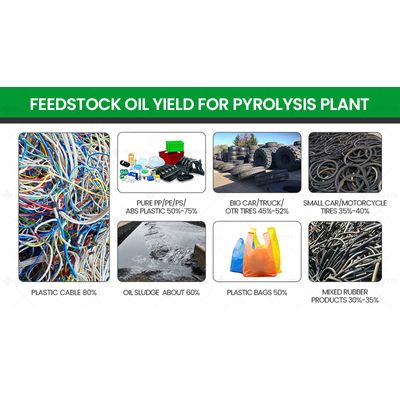

First, **feedstock properties** play a crucial role. The type of material matters: plastics with high hydrocarbon content (e.g., polyethylene) yield more oil than those with additives or lower purity. Moisture and impurity levels also affect output—wet or contaminated feedstocks require extra energy to process, reducing efficiency and oil yield.

Second, **temperature control** is vital. Pyrolysis occurs within a specific range (typically 300–600°C). Too low a temperature leads to incomplete decomposition, leaving unprocessed residues. Excessively high temperatures, however, cause secondary cracking, breaking oil molecules into gases, thus lowering liquid output. Maintaining a stable, optimal temperature is key.

Third, **residence time**—the duration materials stay in the reactor—impacts yield. Insufficient time results in incomplete conversion, while overly long residence time may lead to over-pyrolysis, favoring gas production over oil. Balancing residence time with temperature ensures maximum liquid output.

Fourth, **reactor design and pressure** matter. Well-designed reactors promote uniform heat distribution, preventing hotspots that waste energy or degrade products. Pressure conditions (atmospheric vs. vacuum) also influence oil yield: vacuum environments can lower boiling points, reducing energy use and enhancing oil collection.

In summary, feedstock quality, temperature, residence time, reactor design, and catalyst use are critical factors determining the oil output of a pyrolysis machine. Optimizing these variables is essential for efficient and high-yield operation.