- Home

- Companies

- Henan Doing Machinery Equipment Co., ...

- News

- Why is PVC not used for pyrolysis?

Why is PVC not used for pyrolysis?

PVC (Polyvinyl Chloride) is rarely used in pyrolysis processes—whether for waste-to-energy, fuel production, or chemical recycling—due to severe environmental hazards, equipment damage risks, and poor economic viability associated with its chlorine-rich composition. Below is a detailed breakdown of the core reasons:

1. Releases Highly Toxic Chlorinated Compounds

PVC contains ~57% chlorine by weight, which dissociates during pyrolysis (typically conducted at 300–800°C). This leads to the formation of two categories of dangerous pollutants:

Hydrogen Chloride (HCl): A corrosive, toxic gas that irritates the respiratory tract, damages lung tissue, and poses acute health risks to workers. Even low concentrations (5–10 ppm) cause eye/nose/throat irritation, while high levels (>1000 ppm) can be fatal.

Persistent Organic Pollutants (POPs): Chlorine reacts with organic molecules in PVC (or other mixed wastes) to form dioxins and furans—some of the most toxic substances known. These compounds are:

Bioaccumulative: They build up in the food chain (e.g., in soil, water, and animal fat) and remain in the environment for decades.

Carcinogenic/Mutagenic: Linked to lung cancer, reproductive harm, and immune system damage in humans, even at extremely low exposure levels.

2. Corrodes Pyrolysis Equipment

HCl gas is highly corrosive to the metals (e.g., carbon steel, stainless steel) used in pyrolysis reactors, pipes, and condensers. Over time:

- It reacts with metal surfaces to form metal chlorides (e.g., iron chloride), causing pitting corrosion and weakening equipment structural integrity.

- Corrosion leads to frequent leaks, equipment failures, and shortened lifespans (e.g., a reactor designed for 10 years may fail in 2–3 years if processing PVC).

- Even with corrosion-resistant materials (e.g., Hastelloy, titanium), costs skyrocket—making PVC pyrolysis economically unfeasible for most operators.

3. Contaminates End Products (Fuel/Oil)

A key goal of waste pyrolysis is often to produce usable fuels (e.g., pyrolysis oil) or chemical feedstocks. PVC ruins this by:

- Adding chlorine residues to the pyrolysis oil (typically 1–5% chlorine content). Chlorinated oil is unusable as a fuel:

- It corrodes engines, boilers, and storage tanks.

- Burning it releases HCl and dioxins, violating emissions rules for transportation or industrial use.

- Requiring expensive post-treatment (e.g., catalytic dechlorination, solvent extraction) to remove chlorine. These processes add 30–50% to operational costs and reduce oil yield (by 10–15%), erasing any potential profit.

4. Poor Energy and Material Recovery

PVC’s pyrolysis efficiency is inherently low:

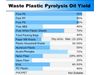

- Chlorine acts as a catalyst poison, deactivating catalysts used to optimize pyrolysis reactions (e.g., zeolites for breaking down long polymer chains). This reduces fuel yield by 15–25% compared to chlorine-free plastics (e.g., PE, PP).

- The energy required to treat HCl and POPs (e.g., running scrubbers, thermal oxidizers) often exceeds the energy gained from burning the resulting pyrolysis oil—making the process energy-negative in many cases.

PVC’s high chlorine content makes it a "toxic burden" for pyrolysis: it endangers human health, destroys equipment, ruins end products, and is economically unviable even with advanced controls. For these reasons, the pyrolysis industry universally avoids PVC, focusing instead on chlorine-free wastes (e.g., PE, PP, rubber, or organic matter) for safe, profitable recycling.