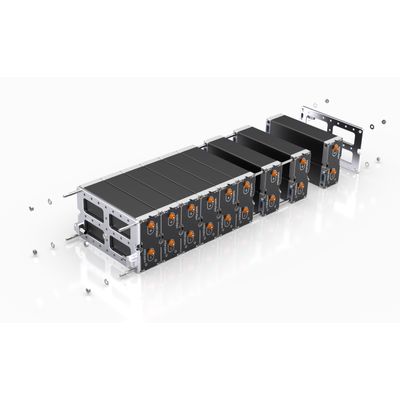

A modular battery system designed for small and medium series : more cost effective, more flexible and faster to implement.

Would it be for a full electric or a fuel cell hybrid application, all vehicle and machine manufacturers have access to a simple and efficient solution for clean power.

Each vehicle type requires a minimum of engineering work depending on the needed performance and work environment. WATTALPS solution requires only a few weeks of engineering for implementation. The R&D phase is thus considerably reduced.

WATTALPS batteries being modular, integrators can capitalize on their developments on their whole product range and therefore significantly improve their return on investment.

- Construction equipment

- Material handling equipment

- Special machines

- Agricultural applications

- Marine

- Municipal vehicles

Our lithium-ion battery modules are used to manufacture mobile charging stations, allowing to quickly start your works with clean energy.

With their remarkable energy density, WATTALPS batteries are also well adapted for an integration into cars. Our modular batteries enable to turn IC engine vehicles into fully electric ones or to design new full electric vehicles easily.

WATTALPS’ goal is to offer a range of standard and modular products so as to make their integration into vehicles or charging stations faster, more efficient and more cost effective. Custom developments of specific auxiliaries can be studied upon request.

We offer several types of battery modules, all fitting in the same casing, with the same interface, which can be split in 3 families:

- Long life module

- High energy module

- High power module

Thermal regulation system

This « brick » controls and optimizes battery temperature in order to improve life, safety and performance. This system can be chosen in three different configurations. A base sub-system ensures homogeneous temperature in the battery system and can be completed by a heating sub-system or a heating/cooling sub-system depending on the climatic constraints to fulfill.

This « brick » is the central control unit of the battery which includes power connections communication and safety control. It also includes current management (current sensor, isolation check, contactors, fuse…). It is available in two configurations for low and high voltage applications.