Organic-Power - Model Maltin -Anaerobic Digestion Plant

Anaerobic digestion is the natural breakdown of organic materials into methane and carbon dioxide gas and fertiliser. This takes place naturally, or in an anaerobic digester.

A typical anaerobic digester is a sealed vessel, or series of vessels, in which bacteria act without oxygen. The organic material contents need to be fully mixed and warmed, usually to blood temperature.

Biogas is the name given to the mixture of gases formed during the anaerobic digestion of organic wastes.

Biogas consists of methane (c70%) and carbon dioxide (c30%).

It can be used in stationary engines to generate electricity, but it is not suitable as a vehicle fuel

After removing the carbon dioxide (and other trace gases using a variety of methods in a process known as upgrading) the remaining methane is known as Renewable Natural Gas or Biomethane.

Biomethane is virtually identical to natural gas, the main difference being that it is produced in days, rather than taking millions of years, billions of years ago.

The uses for biomethane are therefore as varied as are those for natural gas, for heating, cooling, as a source of chemicals, fertiliser or hydrogen.

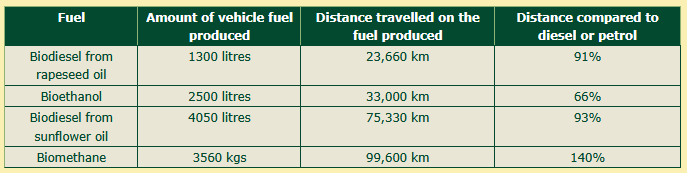

When used as a vehicle fuel, biomethane is, without doubt, the world’s cleanest and most environmentally friendly fuel.

Carbon dioxide is valued for its properties as an inert gas, for heat transfer, and as a solvent.

Common uses include:

- fire extinguisher systems

- carbonation of soft drinks

- freezing or chilling of food products

- decaffeination of coffee

- shield gas in welding

- oil extraction; pumped into an oil well it dissolves the oil

- respiration stimulant for medical use

- propellant in aerosol cans

- food production in greenhouses

- in its supercritical form, as the most environmentally friendly solvent

Compost produced from a thorough and complete treatment system such as the Maltin® System ensures that all the material is broken down into its most basic chemical components with:

- no contaminants

- no smell when dry or when wetted

- no pathogens

- no weed seeds

In a thorough system such as the Maltin® System there is no waste product.

At Organic Power we maintain that WASTE is merely the result of poor or incomplete processing. A properly designed process will not produce any waste (UK Environment Agency, please note).

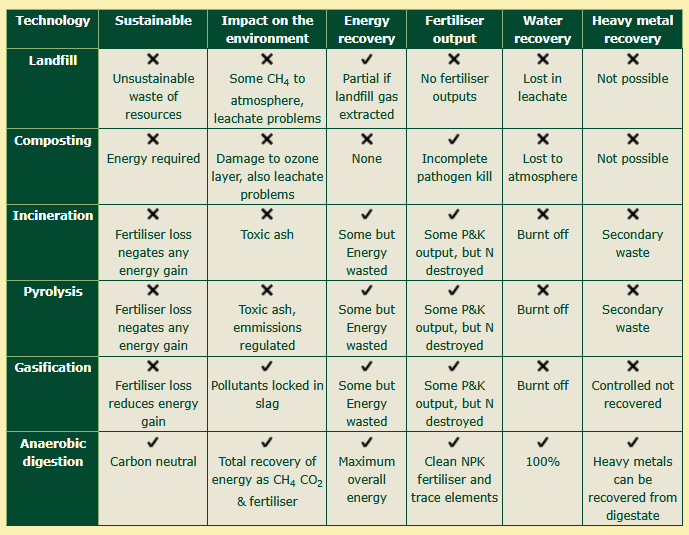

There are essentially three main options for dealing with organic wastes:

- bury it - which means landfilling

- burn it - which means incineration, gasification or pyrolysis

- bio-digest it - which means either anaerobic digestion or composting

Anaerobic digestion is the only system for dealing with organic waste which is sustainable, recovers the maximum energy, is a completely closed system with no emissions to air or land, which retains the fertiliser and water content, and facilitates the recovery of heavy metals.

The Maltin® System has been developed as an entirely new concept for the digestion process based on a series of low energy shaped tanks. The system offers very significant advantages over existing anaerobic digestion technologies available in the market for treating organic wastes.

Mechanical advantages of the tank shape

- mixing is thorough and complete

- heating is applied only at the points where it increases circulation within the tank

- simple to construct

- no fixed or moving parts inside the tanks

Biological advantages of the tank shape

- the minimum energy shape ensures that all the organic material is available for digestion, all the time

- a series of tanks is used to facilitate the different families of bacteria establishing themselves more quickly

- the fluid dynamics within each tank ensure plug flow through the system so that each stage of the process, with different bacteria, has time to be completed

The tanks are placed in a lagoon of water.

Lagoons are:

- available worldwide

- an established and well tried technology

- can be dug using local labour

- zero visual impact – no tall towers or industrial appearance

- appeals to planners

- appeals to farmers who are comfortable with lagoons, but not with industrial plant

Placing the tanks in a lagoon of water has many advantages:

- No propensity for leakage:

- no smell as any minute gas leaks or liquid seepages are immediately obvious

- such minute leaks are invariably at joints, so simple to rectify, but almost impossible to find on a `traditional` above ground system

- very low stress on tanks and joints as the hydrostatic forces are all in balance

- very safe as tanks cannot collapse, buckle or fall over

- Heatretention and stabilisation

- solar energy can be used to heat the lagoon

- the lagoon acts as a large heat sink

- temperature falls at only 0.7 degrees centigrade per day when the heat is turned off

- energy requirements are minimal as the tanks are surrounded by warm lagoon water to reduce heat loss

The tanks and pipes are made of plastic, usually recycled high density polyethylene, which is fully recyclable.

Plastic:

- is completely inert

- has a very low life cycle impact

- is available worldwide

- is 100% recyclable

- has very low heat conductivity

- does not corrode

- has a long life

Corrosion is mainly caused by hydrogen sulphide which is generated during anaerobic digestion.

This is a serious problem with digesters, corrosion affects not just the tanks but also:

- electrical connections

- pipe joints

- gas meters

- gas compressors

- mixing paddles

Corrosion in the Maltin® System is virtually eliminated because:

- the tanks are placed in a lagoon and there are no gas leaks which are the main cause of corrosion

- the tanks are made of recycled plastic which does not corrode

- Most other components are also made of plastic:

- pipes and connectors

- gas collection system

- digester mixing system (no compressor or paddles)

Our low-energy shaped multi-tank system can be used for the treatment of a very wide range of organic wastes, either solid or liquid, including domestic and industrial organic wastes, food processing residues, agricultural slurries and energy crops and for cleaning process water.

The Maltin® System can be used to:

- treat organic waste

- convert specially grown crops into biogas

- generate biogas

- upgrade biogas to biomethane for vehicle fuel

- create clean fertiliser and soil conditioner

- create food quality or solvent quality renewable carbon dioxide gas

- create renewable materials such as wood substitutes which are so much better than MDF

Organic wastes can include:

- any biomass, anything which has ever grown

- bacteria do not have teeth, so the more liquid a feedstock, the better it is suited to the digestion process

- where the feedstock is not of a suitable viscosity, pre-treatment is necessary. The Maltin® System includes a high pressure low energy autoclave type pre treatment to ensure that the feedstock is suitably conditioned

- woody substances are not suitable for the Maltin® System

Biogas

Biogas is the name given to the mixture of gases formed during the anaerobic digestion of organic wastes. Biogas consists of methane (c70%) and carbon dioxide (c30%), water vapour, and other impurities and trace gases such as hydrogen sulphide. It can be used in boilers for heating and in stationary engines to generate electricity, but it is not suitable as a vehicle fuel.

It can be used:

- to generate electricity

- for upgrading to biomethane where its uses are the same as those for natural gas

Biomethane

- can be used for heating, cooling, as a source of chemicals, fertilisers or hydrogen, or as a vehicle fuel

Clean fertiliser

- the digestate can be separated into a solid soil conditioner and a liquid fertiliser. The solid conditioner improves impoverished soil structure

The first two natural gas powered Mercedes EcoVitos from the DaimlerChrysler production line (delivered to Horsington for Organic Power who were responsible for the original design concept).

Using the Maltin® System to capture the methane gas given off by the decomposition of organic waste, which would otherwise have escaped to become a greenhouse gas some 21 times more damaging than carbon dioxide, and using this gives the most environmentally friendly vehicle fuel in the world.

Other renewable fuels might be "less bad" for the environment when compared with fossil fuels, whereas using biogas is actually "doing good" for the environment.

Best really means best and biomethane produced from organic wastes is better for the environment than ANY OTHER fuel, including hydrogen, wind power, liquid biofuels such as biodiesel and bioethanol, wave and tidal power, etc.

Some 15 years ago we began an in-depth and ongoing worldwide study of all the existing organic waste treatment and renewable energy systems based on anaerobic digestion to determine why the process had not been taken up on the greater scale it warranted.

We were aware that anaerobic digestion has long been established as the standard method for dealing with sewage sludge in the water industry. However using the process to treat other forms of organic waste had met with a number of significant problems.

We were aware that anaerobic digestion has long been established as the standard method for dealing with sewage sludge in the water industry. However using the process to treat other forms of organic waste had met with a number of significant problems.

This worldwide study resulted in Organic Power successfully developing the Maltin® System which overcomes these difficulties and protective patents are now in place

Our fully instrumented Demonstration Plant, which has been running since 2002, is also used as a research plant producing valuable data, online, real time. Monitoring takes place in all eight tanks to show the different bacterial activity in the separate tanks, the varying amounts of biogas and the differering ratio of CO2 and CH4 in each of the tanks. Analysis is carried out both in our own laboratory and externally for independent verification.

At present there are five areas which are being developed concurrently:

- The installation and monitoring of more advanced forms of the necessary feedstock preparation equipment associated with Maltin® System technology at our headquarters

- The installation of a fully instrumented 6m deep test tank at our UK headquarters which will be used to independently verify the minimal energy input requirements of our system

- A transportable plant for testing different feedstocks which can be taken to sites to demonstrate the technology on the actual materials which require treatment by potential licensees

- The plant at our headquarters will continue to run different fedstocks to demonstrate our technology and to enable the long term independent monitoring of the Maltin® System

We have been carrying out our programme of research in conjunction with Southampton University and the company employs two full time graduate students from Southampton as part of our Team.

Since 2003 Organic Power has been part of the European consortium of 11 partners in 6 European countries which has been investigating how anaerobic digestion can best be applied to provide a versatile, low-cost, carbon-neutral fuel in an environmentally sound and sustainable agricultural framework. The results of all this work can be seen on the Cropgen website, but because of Organic Power`s fundamental interest in clean transport fuels, we have included one of the papers Biohydrogen Production directly on Organic Power`s website.

Mixing a relatively small amount of biohydrogen with biomethane produces what we call biohythane and gives what we believe is by far the most environmentally friendly transport fuel in the world. Although biomethane is so much more environmentally friendly than any other biofuel, by adding the biohydrogen the flame pattern in an internal combustion engine cylinder head is even more improved. The NOx emissions from pure biomethane are considerably less than the emissions from diesel fuels and are even more reduced when running on biohythane, particularly under varying engine load conditions.