Anka - Regenerative VOC & Siloxane Removal Systems

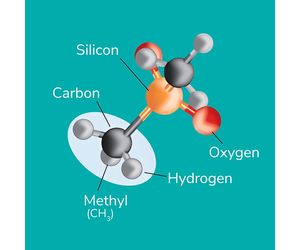

Biogas contains VOCs (Volatile Organic Compounds) and siloxane contaminants that damage downstream equipment used in electricity generation and gas engines. VOCs reduce the performance of treatment systems, clog membranes, decrease efficiency in PSA systems, and increase energy consumption. They also reduce adsorption capacity in Activated Carbon Beds and increase the replacement frequency of activated carbon media. In RNG projects, VOCs may lead to grid injection rejection and costly shutdowns. When siloxane is burned at high temperatures, it reacts with oxygen and transforms into solid Silicon Dioxide (SiO2). This compound does not burn or evaporate. Silicon Dioxide (SiO2) buildup harms pistons, spark plugs, and valves. As a result, the maintenance frequency of the downstream equipments, especially engines, increases, energy cycle losses and knockouts occur, and spare part replacements increase.

Silicon dioxide accumulated in the gas engine damages various parts of the engine such as pistons, cylinder heads, and valves and shortens the life of spark plugs, engine oil, and oil filters. As a result, the maintenance frequency of the engine increases, energy cycle losses occur, and spare parts consumption increases.

Additionally, as a result of the insulating effect of the silicon dioxide covering the thermocouple and knock sensors, the optimal values of the fuel/air ratio of the engine deviate as a result of incorrect values. Therefore, engine efficiency decreases, and emissions increase. In addition, as a result of the failure of the electronic systems that protect the engine from excessive temperature and knocking, heavy damages occur to the gas engines.

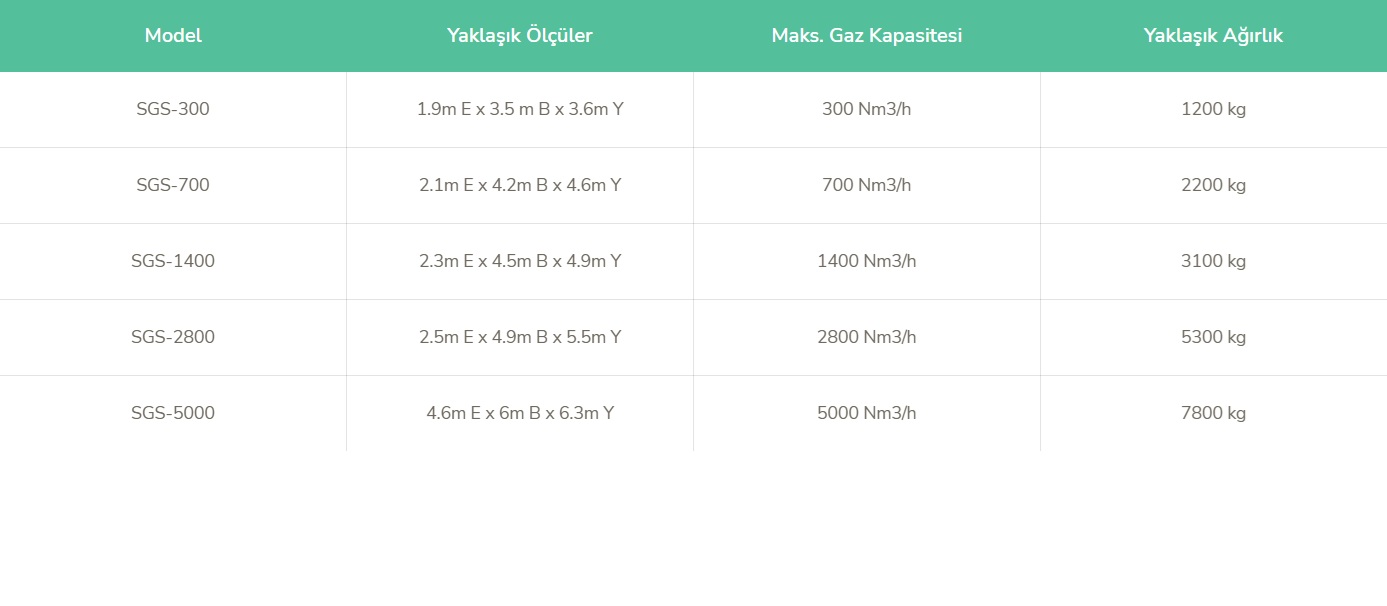

The Siloxane Removal System (SGS), which started as an R&D project supported by the Ministry of Industry, has become a regenerative system that eliminates the need for gas analysis and ensures the continuity of the fuel, which is considered a clean gas. The selective properties of the filter materials used in the Siloxane Removal System both provide an effective purification process and prevent practically impossible applications such as continuous analysis and frequent material change. Thanks to its modularity, the system, which can be easily scaled according to any capacity, has a very low load loss, which is very important for long-term energy savings.

ANKA Siloxane Removal System basically consists of two tanks containing the filter material used in siloxane removal. These tanks work sequentially. When the siloxane removal capacity of one tank is full, the system automatically activates the other tank, while the tank saturated with siloxane is regenerated and made usable again. Thus, clean gas can be supplied to the engines without interruption.

Siloxane Removal System provides 100 % success in the purification of gas streams with intense pollutants such as landfill gas in terms of meeting the performance criteria given by engine manufacturers and guarantees the continuity of these criteria in the light of both purified gas and oil analysis.

As the advantages of ANKA- Siloxane Removal System, the following items can be counted: The material change times are certain and it is guaranteed on the basis of both gas and oil analyses for these periods; the system does not bring additional labor to the facility during its operation; the treatment process continues uninterruptedly; the system is modularly produced according to the needs of the customers.

As a result of the establishment of the Siloxane Removal System, profits are obtained in many cost items at the facilities.

Maintenance

- Overall maintenance costs

- 13.000$/ MW / Year

Spare Part

- Spare parts replacement costs

- 56.500$/ MW / Year

Production Loss

- Production loss during the head reconditioning and unexpected failures causing stoppage

- 21.500$/ MW / Year

Power Loss

- Power loss of the engine due to siloxane deposition resulting in knocking and wearing in gas engines

- 51.000$/ MW / Year