- Home

- Companies

- Rodan Engineering Company Ltd.

- Products

- Rodan - Model RPS EFW - ATD Power ...

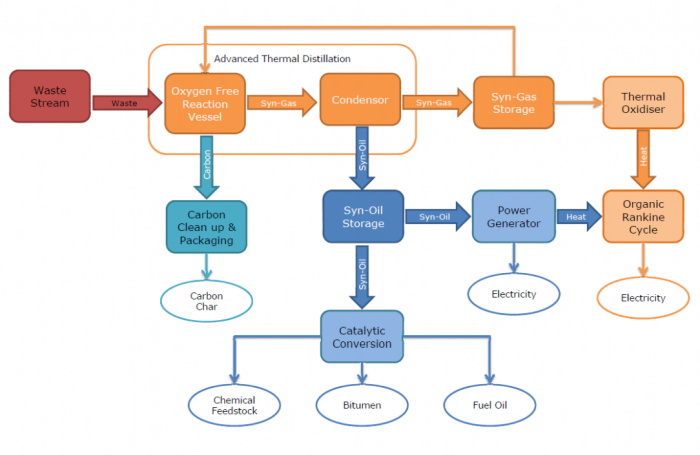

Rodan - Model RPS EFW -ATD Power Generation - Process Flow

How we produce power: Using conventional chipping, pelletising, composting or anaerobic digester technology, a consistent and regular shaped fuel is produced from the input waste stream. The prepared fuel is then fed into the M3RP pyrolysis retort (sealed chamber) through airlocks.How we produce power: Using conventional chipping, pelletising, composting or anaerobic digester technology, a consistent and regular shaped fuel is produced from the input waste stream. The prepared fuel is then fed into the M3RP pyrolysis retort (sealed chamber) through airlocks.

Inside the retort the materail is indirectly heated to 600°C - 850°C (dependent on material and legislative requirements) in the absence of oxygen, by a low NOx burner running off previously produced pyro-gas. The heating in the absence of oxygen causes the materials to denature into their constituent compounds.

The pyro-gas is then condensed and some of it turns to pyro-oil.

The pyro-gas and pyro-oil can then be sent through generators to produce electricity, some of which can be used to run the plant and the majority exported to the national grid.

The more volatile molecules are then free to recombine into calorific pyro-gas that typically contains a mixture of hydrogen, carbon monoxide, methane and other hydrocarbon gases. Not all the carbon in the feedstock is consumed and this exits the pyrolyser through an airlock as a mixture of pyro-char and a small amount of ash.