SHINHOP, Brand of Shenzhen Xinhua Peng Laser Equipment Co, Ltd.

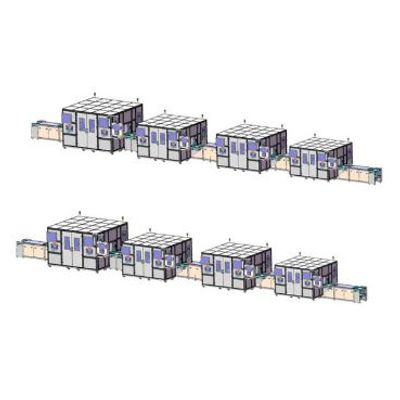

SHINHOP - Battery Welding Assembly Line

It is suitable for the assembly and welding of square power batteries with a length of 100~160mm, a width of 24~39mm, and a height of 80~140mm, such as square lithium-ion batteries, square nickel-hydrogen batteries, and square nickel-carbon batteries.

Most popular related searches

lithium battery

nickel-hydrogen battery

lithium ion battery

hydrogen battery

carbonization

battery production

power line

gas drying

- The hot pressing temperature control accuracy and pressure control accuracy meet the technical needs of brand battery users;

- The installation of Mylar flakes (mylar) has high upper and lower alignment accuracy;

- The welding peeling residue and welding tension between the tab and the adapter sheet meet the relevant technical requirements;

- The welding tension between the tabs and the top cover, the effective welding line width after stripping, the positive and negative electrodes all meet the needs of brand battery users;

- Cover plate sealing welding (top welding/side welding), explosion-proof valve and liquid injection hole welding after formation.

- Clean, high-end appearance and strong usability;

- The system has been actually used by users and has good production results;

- The overall process workstation is fully equipped with tight division of labor and assembly;

- The product yield is high and the production efficiency is good;

- The system integrates loading, cell processing, laser welding, welding inspection, blanking and other processes, with a high degree of automation, which greatly reduces labor costs;

- Each unit of the production line has a modular design and can work independently. The workstations and processes can be flexibly selected to adapt to product process adjustments. It can be paused and started independently or the equipment can be manually processed;

- The production line has reserved industrial communication interfaces to facilitate remote monitoring and management, and can be connected to the MES system to achieve comprehensive traceability of product information.

It can realize automatic loading and unloading, cell hot pressing, tab pairing and welding, cover plate welding, quality inspection, glue application, cell insertion into shells, etc. to achieve automated assembly production.

- Product name: Square battery cell welding and assembly production line;

- Power supply requirements: 380V±10%, 50Hz;

- Gas supply requirements: dry compressed air <200L/MIN, pressure>0.6Mpa, high-purity nitrogen <5L/MIN, pressure>0.4Mpa;

- Vacuum: -101kpa~-50kpa, staffing: 2-3 people;

- Failure rate: ≤2%; pass rate: ≥97%; scrap rate: ≤0.4%;