Biochar: Concentrated Carbon with Mineral

The biochar is concentrated carbon with minerals. Depending on the origin of the biomass, it may also contain interfering substances, which may have consequences for the applicability of the biochar or a possible subsequent process. There are three possible applications that seem promising.

- Biochar as a soil improver. A certain volume per hectare is added to the soil. The carbon is fixed in this way for centuries and the porosity of the carbon ensures the retention of moisture in the higher soil layers. When the biomass is the remainder of, for example, bulbs or remains of greenhouse cultivation, the minerals can ensure the remineralization of the soil and certain minerals can be made circular in this way.

- Biochar as a raw material for the biobased economy. The carbon from biochar can be used in various ways, such as in bio-composite or bio-dyes.

- Biochar can receive a thermal follow-up treatment that removes contaminants and the carbon content exceeds 97%. The porosity will then also increase to a surface area of around 1,500m² per gram. This creates activated carbon that can be used in various cleaning processes.

Haffner already started in 2012 with the first steps to develop the Hynoca® technology, which eventually led to a first order for a commercial project. The client was R-GDS from Strasbourg, part of the French Gasunie. This project has been operational since June 2021 and is performing above expectations.

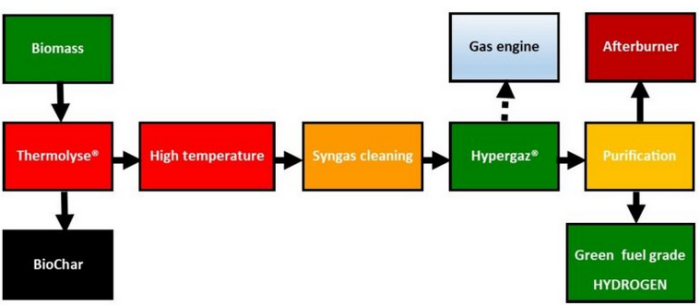

In the thermolysis step, the biomass is separated into a solid and gaseous fraction. More than 50% of the carbon enters the biochar and the gaseous fraction undergoes a high temperature process in the second stage. The resulting syngas is purified with water, oil and activated carbon. This creates Hypergaz. This in itself almost clean gas can be burned in a gas engine to get heat and electricity. This will only happen in a project if the amount of hydrogen in the initial phase is too large to be sold.

Normally, the Hypergaz will undergo another purification step to achieve high-quality (fuel grade) hydrogen. This hydrogen is preferably used locally for mobility, industry or the introduction into a hydrogen network. The contaminants from this purification step are small because a previous purification has already taken place. This residual contamination, including a small amount of Volatile Organic Compounds, will be destroyed in an afterburner. The heat that is released is sufficient for the process to take place fully autothermally. The part of the carbon that has not entered the biochar will be released here as CO 2 and can be used to seal off the biochar and some seals in the system against outside air entry.