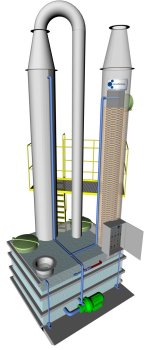

Model DESOLF-TR Series -Biogas Desulphurization Venturi Tower

Operating Principals: In anaerobic fermentation of waste for biogas production, the methane produced contains high levels of hydrogen sulphide which is highly corrosive to the energy production unit. Ecochimica’s desolf equipment reduces the quantities of hydrogen sulphide with a 90% efficiency and through careful chemical cleaning of the biogas.

First Tower Stage (TW1):

In the first tower, the biogas is backwashed at low velocity over an ample static contact surface (biogas - wash solution) obtained through alveolar exchange packs with a high specific surface area..

Second Tower Stage (TW2):

In the second tower, the biogas is scrubbed in the same way as in the first tower and then passes through a demister: alveolar packs to separate droplets which prevent the reagent solution carry-over..