- Home

- Companies

- Ecological Laboratories, Inc. (ELI)

- Products

- Ecological - Model BGE1 - Biogas ...

Ecological - Model BGE1 -Biogas Production with Live Liquid Microorganisms

Several trials have been conducted to showcase the diversity of the technologies capability to adjust to different feedstocks. An anerobic digestor operator in N. Ireland, displaying high levels, of hydrogen sulfide at 270 ppm and low methane output. The trial was conducted with daily treatment of BGE1 and BGE2 on an 600,000-gallon anaerobic digestor with a combined feedstock of grass, chicken litter, and manure slurry.

BGEi by ELI BioSctences

- Effectively eliminates and controls hydrogen sulfide

- Digests solid organic waste, grease, fats and oils

- Maximizes the production of biogas

- Enhances biogas methane percentage and heat value

- Eliminates foaming and solids buildup

- Reduces shut down time

- Increase loading capacity

- Enhances and drives startup of biogas unit

- Increases digestate plant availability

- Safe. Easy to Apply. Effective

BGE1 by EU Biosciences has a hydrogen sulfide odor which will dissipate qukkty.

Using natural biological activity, that* 100% natural and beneficial bacteria will decrease maintenance and increase efficiency.

BGEi by Eli BioSciences comprises several biological strains. H Is a special mixture of bacteria designed specially for anaerobic digester process enhancement

- Promotes all four stages of anaerobic digestion

- Drives the first stage of hydrolysis

- High counts of archaea. proven to be the driving for of methane generation

- Effective in passive, low rate, and high rate systems

Directions

For system enhacement. apply in a 50/50 mixture with 6GE2 directly into feedstock (as recommended by our technical staff or distributor).

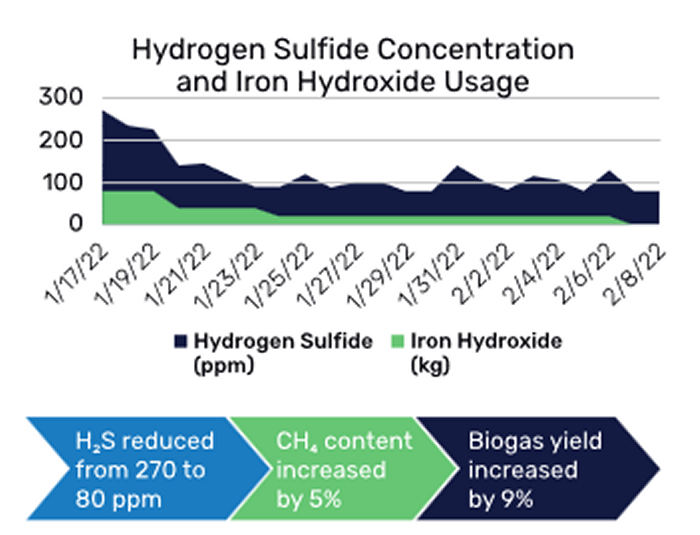

Several trials have been conducted to showcase the diversity of the technologies capability to adjust to different feedstocks. An anerobic digestor operator in N. Ireland, displaying high levels, of hydrogen sulfide at 270 ppm and low methane output. The trial was conducted with daily treatment of BGE1 and BGE2 on an 600,000-gallon anaerobic digestor with a combined feedstock of grass, chicken litter, and manure slurry.

Results

Hydrogen Sulfide Concentration and Iron Hydroxide Usaae

Eli Biosciences effectively increas biogas yield and methane percentage, while reducing hydrogen sulfide levels by 70% after 21 days of treatment. Completely removing his annual cost of $40,000 for iron hydroxide input.

The Biogas Series by Eli Biosciences supports each stage of anaerobic digestion.

The microbial technology promotes process improvement with high fat and protein food waste as ELI`s microorganisms exhibit exceptional enzymatic breakdown and cleavage within Hydrolysis assuring problem free transition to acidogenesis, with limited to no build of FOG, scum, or foam.

Separate strains, including archaea, drive the conversion of fatty acids, leading to higher methane outputs.

Highly specifically to speed up the biological degradation of hard to degrade compounds in anaerobic digestors. Contains purple sulfur - non-sulfur to support hydrogen sulfide reduction and methanogens to drive methane production.

- Effectively eliminates and controls hydrogen sulfizde

- Maximizes production biogas

- Enhance biogas methane percentage and heat value

- Reduces shut down time

- Increase loading capacity

- Enhances and drives startup of biogas unit

- Increases digestate plant availability

- Safe, Easy to Apply, Effective

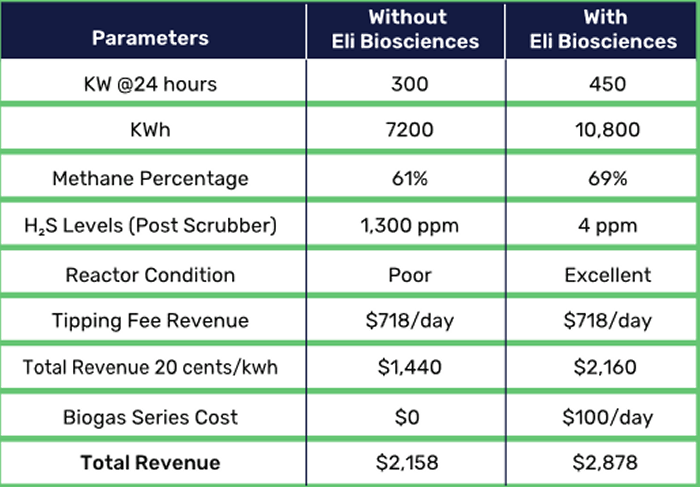

BIOGAS SERIES BRINGS INOPERABLE DIGESTOR BACK TO LIFE

The Holstein Family Farm in Pennsylvania, operating two 150,000-gallon anerobic digestors, were facing severe concerns with their reactors. The combined feed stock of poultry waste and dairy manure are extremely high in: FOG`s, Protein, and chemical constituents. Difficulty breaking down these organics resolved in bulking, low methane output, and exceedingly high hydrogen sulfide levels.

Following treatment with Eli Biosciences™, the reactor`s performance shifted dramatically. The methane percentage grew by 10%, solids were completely eliminated from the balancing tank, and hydrogen sulfide levels were undetectable.

Holstein Farm Generates an additional $720 per day with application of the Biogas Series, or a 7x return of investment. This does not factor in other benefits including operating efficiency, reduced shut down time, H2S reduction, and cost saving for replacement of equipment (H2S scrubber and Motors).