- Home

- Companies

- Ammongas A/S

- Products

- Ammongas - Biogas Upgrading Plant

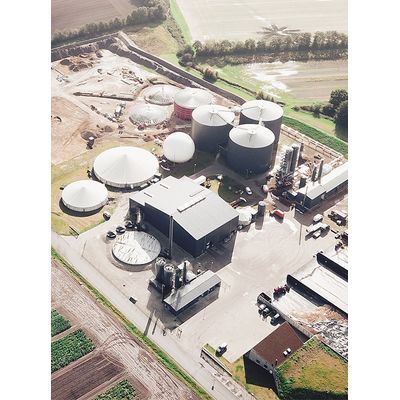

Ammongas - Biogas Upgrading Plant

Ammongas uses the well-known absorber-stripper system with amine for upgrading of biogas. The process has been used for many years in the oil and gas industry for removal of CO2, H2S other acidic gasses, and is known for being a robust and reliable system. Ammongas’ absorption process is so efficient that the methane slip to the atmosphere is less than 0.05%. This means that the amount of methane gained is more than 99.95%. Due to the efficient process a high concentration of methane in the separated biomethane stream of 99% can be achieved. Furthermore, Ammongas’ amine upgrading can remove down to less than 50 ppm of CO2 in the biomethane stream, and thereby prepare the gas for liquefaction. The robust technology and process of the upgrading process, results in low operational expenses, as well as a high up-time, with an average up-time of 99% including service.

We use our experience and expertise and cooperate with you to tailor the plant to your specific needs.

Expensive pre-treatment of biogas is not necessary with an upgrading plant from Ammongas.

An upgrading process with pressure saves a lot of costs in the building phase and less expenses in maintenance.

The parts in na upgrading plant from Ammongas are robust and of high quality, which ensures a long life.

1. The raw biogas enters the absorber column

The raw biogas enters the absorber column without any pre cleaning directly from the gas storage. The biogas Is washed with a watered-down amine solution, where the CO2 (and other acidic gases as H2S) are absorbed into the amine solution. This process is pressureless, and there is no need to compress the heavy CO2, and the methane is only compressed to the needed pressure.

When the gas leaves the absorber column the biogas has been upgraded to biomethane. After the upgrading the gas is polished in an active carbon filter before the gas is compressed to the needed pressure for the gas grid. The gas is then dried and cooled before the final injection to the gas grid.

2. Pumped to desorber column

After the amine solution has absorbed the CO2 from the biogas, it is pumped into the desorber column (stripper column). The amine solution is heated, typically by the boiler which supplies heat to the biogas plant.

By heating the amine solution CO2, H2S and steam will leave the desorber column, and the amine is pumped back to the absorber column and is ready to absorb CO2 and H2S again. In this way the amine solution is used in a closed circuit, and the amine consumption is minimal.

3. Heat recuperation

The heat from the boiler which leaves the desorber column along with the CO2 and steam can be recuperated. Typically, it is possible to recuperate 30-40% of the added heat at about 80-90°C, depending on the feed temperature.

Likewise, it is possible to recuperate the middle temperature from the amine cooling at 50-60 °C, typically 40-50% is recuperated at this point. If recuperation from the compressors is added, it is possible to achieve >90% heat recuperation with an amine-based upgrading plant by Ammongas.