Biogasclean - Model MBR -Biological Desulfurization of Biogas and CO2

MBR – Moving Bed Reactor – is Biogasclean’s patented technology for cleaning biogas with a high sulfur content. The MBR technology is especially developed for biogas formed during treatment of wastewater on molasses ethanol distilleries. Gas bubbles through liquid with moving media. After compression, cooling and air injection the raw biogas with H2S is led through the gas bubble diffusers in the bottom of the MBR tanks. The biogas bubbles up through the digested wasterwater. The packing media is floating in the scrubber liquid and no special cleaning is required. MBR – How it works. Watch the video and learn how Moving Bed Reactor(MBR) works.

- The H2S is oxidized to elemental sulphur and the MBR effluent has the same pH as the digester effluent. The MBR effluent can be passed to the storage ponds after the digesters and be recycled to irrigation or evaporation. The sulfur sludge in the MBR effluent can also be separated from the liquid in solid form.

- MBR gives several advantages. The MBR is a closed system and has no emissions or odor issues. The oxygen in the clean gas and the dilution of the methane is very low. Maintenance is limited to general industrial equipment like pumps, gas blowers and gas diffusors.

- MBR versus chemical and biological scrubbers. Lowest CAPEX and OPEX of any H2S removal technologies for biogas produced on molasses ethanol wastewater.

- Patents. The new gas cleaning technology is groundbreaking. Patents have been obtained in United Kingdom, Germany, France, Belgium, the Netherlands, USA, Brazil, China and India while our national patent application in Thailand is still ongoing.

- MBR process – Learn more

The MBR technology is especially developed for larger biogas flows produced on wastewater from molasses or cane juice at ethanol distilleries where the biogas has high H2S loads (15,000-30,000 ppm) in combination with low calorific values (50-55% CH4). Biogasclean MBR is patented and have the following key features:

- The PTU – the Process Technique Unit - is the technical equipment necessary for safe and automatic operation. The technical equipment is skid mounted and comprise a.o. gas blowers, gas pre-cooling system, air blower system and liquid supply system. The PLC based control system as well as the frequency converters are installed in an air-conditioned control room.

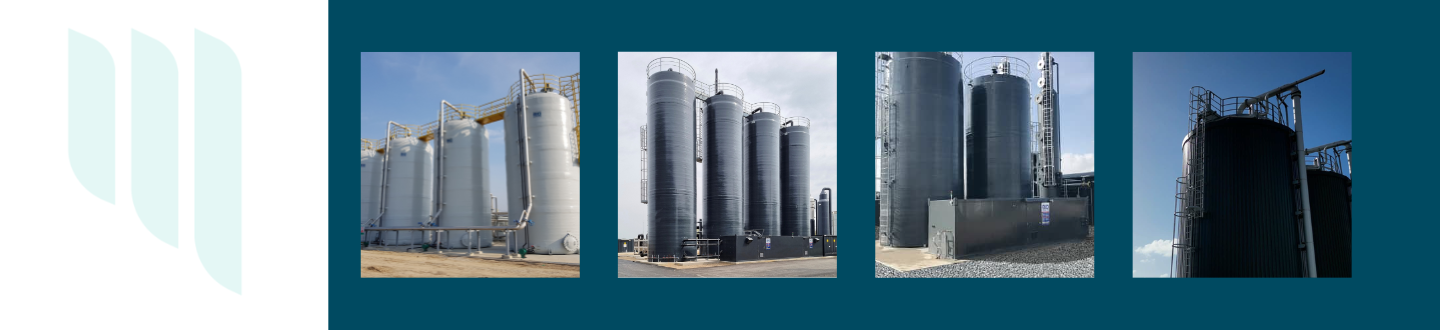

- MBR tanks. Comprise one or more insulated tanks manufactured in high quality fiber glass. Depending on the H2S volume we use either prefabricated tanks or field erected tanks.

- MBR packing media. The raw biogas is – after injection of air or oxygen - bubbled through the liquid containing the high-surface MBR media. The packing media is floating in the scrubber liquid and no special cleaning is required.

- Foam control. The foam produced by bubbling the gas through the liquid is controlled by injection of small amounts of palm oil based on online process parameters monitored by the PLC.

- MBR (Moving Bed Reactor) versus BTR (Bio Trickling Reactor). If the raw biogas is below 1,000 Nm3/h the BTR will normally be the most cost effective solution, whereas the MBR technology is superior if the flow of raw biogas is above 1,000 Nm3/h

Plant: KSL Green Innovation PCL Thailand

Capacity: 5,000 m3/h (2,941 scfm) biogas 15,000 ppm H2S

Plant: Power Solution Technologies (PSTC) Thailand

Capacity: 3,000 m3/h (1,765 scfm) biogas 15,000 ppm H2S

MBR – Moving Bed Reactor – is Biogasclean’s groundbreaking and patented technology for cleaning biogas with a high sulfur content. The MBR technology is especially developed for biogas generated on waste waters with high organic loads such as ethanol distilleries. The MBR has a very compact design and only requires 25-30% tank volume compared to biotrickling.

The most important differences between Biogasclean’s solutions and alternative biological H2S removal systems are safety and automatic reliable operation.

- Safety. Injection of air into biogas is possible with a control system; without there is a substantial risk of creating dangerous situations with explosive mixture. Therefore, Biogasclean systems are supplied with a control system which will adjust air injection to the actual biogas flow and stop air injection in case there is no biogas flow. If the PTU is closed, the safety system will also remove the ignition source by cutting the power supply in case the gas detector should measure methane above 25% of the Lower Explosive Level (LEL).

- Safety – Learn more ?

- Automatic reliable operation. Safety is mandatory; but on top of that the control system also secures good performance even with fluctuations in the biogas flow. The system is automatically controlled by the PLC controller board which reduces the risk for manual errors and operation problems. The main function is to provide safe, optimal and stable conditions for the biological process. The signals can be made available in the control room.

- Low operating costs. The system uses no chemicals and has a very low electrical consumption. In many projects we use treated water from an anaerobic digester or an aeration pond as scrubber liquid and nutrient source. This is easily accessible and cheaper than water and industrial fertilizer.

- Guaranteed performance. We provide performance guarantees on all projects.