- Home

- Companies

- Henan Mingjie Environmental Equipment ...

- Products

- Mingjie - Model MJT - Biomass ...

Mingjie - Model MJT -Biomass Carbonization Plant

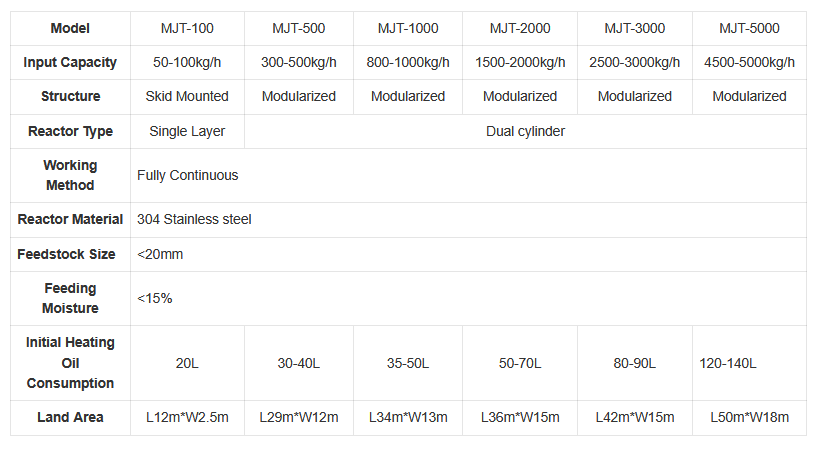

According to the different biochar making machine structures, Mingjie biomass carbonization plant can be divided into skid-mounted small biomass pyrolysis plant and modular continuous biomass to biochar making machine. The small biomass pyrolysis machine adopts an integrated skid-mounted structure, and the capacity of processing waste biomass is 50-100kg/h. The skid-mounted carbonization equipment tightly integrates the pyrolysis reactor, cooling system, intelligent control module and purification system.

The double-barrel reactor can improve the continuity and reliability of the use of pyrolysis equipment, and realize the integration of material drying and carbonization. It can ensure that the content of the produced biomass carbon meets the ideal requirements.

The biomass carbonization plant realizes the continuous feeding of biomass and the continuous discharging of biochar, which can meet the needs of large-scale industrial production. The large-scale biochar making machine is equipped with an automatic feeding conveyor belt and a spiral discharging device. The biomass raw materials continuously enter the pyrolysis reactor through the conveyor belt. After the pyrolysis process is completed in the reactor, the biochar is continuously output by the spiral discharging device.