Akkaya

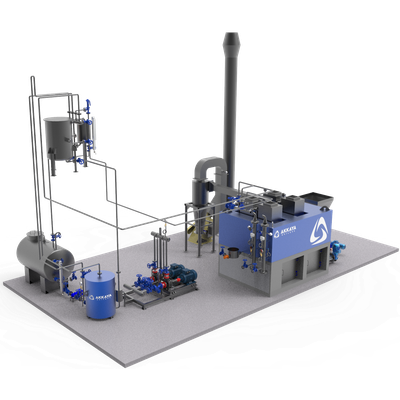

Akkaya - Model KYK HLZ Series -Biomass/Coal Thermal Oil Heaters

FromAkkaya

Heat generation capacity: 116 kW - 8720 kW. Fuel Type: Biomass, Coal, Pellet, (Natural Gas, LPG, Diesel, Fuel Oil - Optional). Capability to operate with low flue gas temperatures and high efficiency thanks to its horizontal design with helizoidal coiled tubes.With heat transfer oils of suitable chemical content, can safely reach a high operating temperature such as 300oC with 6 bar operating pressure.

Most popular related searches

thermal oil heater

boiler tube

energy consumption

combustion system

industrial boiler

gas burner

natural gas fuel

coal oil

oil burner

biomass pellet

- Thermal oil heaters, designed in such a way that the velocity of the oil in the coil is in the range of 2.5 – 3 m / sec, ensures the protection of the chemical structure and heat carrying capacity of the heat transfer oil.

- Oil and gas side pressure losses are low. Thus, the investment cost and energy consumption of the selected equipment is lower.

- By obstructing the thermal bridges that may occur while lifting or by insulation substructure materials on the heater body, thermal losses are minimized.

- Can be supplied with open or nitrogen cushioned expansion tank.

- Front cover and back wall insulation are provided with high heat resistant refractory concrete and ceramic blanket with minimum heat loss.

- Upon request, it can be designed, manufactured and commissioned with the economizer unit.

- Provides safe and stable operation thanks to high quality safety equipment.

- Thanks to PLC controlled touch screen control panel, quick technical support can be obtained from anywhere in the world with easy operation and remote access from mobile devices.

- Shipped with long-lasting insulation that minimizes heat losses.

- Production in accordance with EN12952 and PED2014/68 CE directives

- Welding check of our boilers is carried out with non-destructive testing (NDT) within the scope and ratios specified in EN 12952-6.

- Our welded productions are carried out by certified welders according to approved WPS and WPQRs. MIG-MAG and SMAW welding techniques are applied during production in accordance with the norms.

- They are manufactured by using high quality, certified boiler sheet and seamless boiler tubes in accordance with standard requirements.

- Akkaya high efficiency and horizontal thermal oil heater with helizoidal coiled tubes

- Combustion System (Automatic fuel feeding stoker, water cooled vibrating grate, manual grate or oil/gas burner)

- High quality heater oil inlet and outlet valve Heater oil inlet and outlet temperature sensor

- Heater oil inlet and outlet pressure transmitter

- Heater oil inlet and outlet manometer and 3 way connection valve

- Heater oil inlet and outlet pressure switch

- Heater oil inlet and outlet thermometer

- 1 operating ,1 stand-by ,long lasting thermal oil circulation pump group with inlet valves, filters, compensators and check valves

- Heater oil inlet and outlet air vent valve

- Flue temperature sensor

- Heater leakage tank and accessories

- Thermal oil filling pump and accessories

- Deaerator tank and accessories

- Expansion tank and accessories (open or nitrogen cushioned closed type)

- PLC based touch screen and remote access control panel

- Economizer, Recuperator (Optional)