Shanghai Haiqi Environmental Protection Technology Co.,Ltd.

- Home

- Companies

- Shanghai Haiqi Environmental Protection ...

- Products

- Biomass Gasification for Boiler System

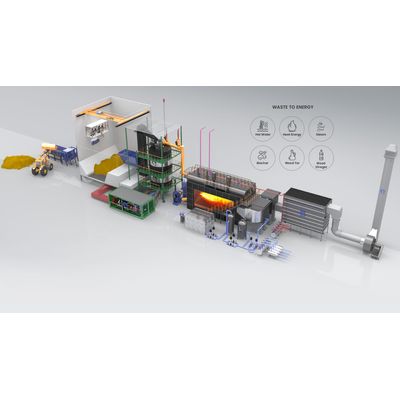

Biomass Gasification for Boiler System

Raw material: wood chips, straw, pellets, nut shells and other biomass raw materials. Main energy: heat energy, electricity energy, syngas, biochar, wood vinegar, wood tar. Application field: textile printing industry, food industry, drying industry, smelting industry.

Most popular related searches

biomass gasification system

biomass gasification

boiler system

biomass gasification boiler

gasification system

gasification boiler

biomass boiler system

biomass system

energy consumption

energy saving

Haiqi Focus on Alternative Energy Services,Customized solutions for long-term operations and maintenance for projects of all sizes.

More Environmentally Friendly, Low Energy Consumption, Large Tonnage, Low Investment Cost And Fast Return

- Haiqi gasification boiler system adopts low-nitrogen biomass gasification burner, which is more stable to connect with industrial boilers.

- Green energy,environmentally friendly and energy-saving, and the emission standard complies with the latest EU2019 standard.

- The whole system uses the 5G smart energy management system which independently developed by Haiqi, it can reasonably match the energy utilization rate of the system.

- The energy consumption of the system is lower, and the comprehensive efficiency of the gasification boiler system is ≥90%. Low investment and high return, Haiqi industrial gasification system can be customized according to customer requirements.

- The power of a single system is 350kw~17MW, which saves the cost of single system for customers and speeds up the return on investment.

- It can replace natural gas and oil and other fossil energy effectively, reduce the operating cost of enterprises, and improve the market competitiveness of products.

- The cost of biomass gas is only 20%~30% of the cost of natural gas, and its economic value is considerable, which has an absolute advantage in industrial transformation projects.

Efficient And Stable, More Intelligent, More Secure

- The comprehensive efficiency of the gasification system is ≥80%, the eefficiency is high, Cogeneration of carbon gas or only industrial gas can be provided according to customers` requirements.

- The system can automatically adjust the energy consumption according to its own operating conditions.

- The system can realize one-click start and stop function, making energy saving transformation easier.

- The hardware facilities of the system are equipped with multiple explosion-proof intelligent valves and intelligent sensing systems, which can ensure the safe and stable operation of the system without manual intervention after system faults.

High Energy Conversion Efficiency And Low Operating Cost

- Haiqi biomass gasification system has a high energy conversion efficiency and can provide personalized solutions according to customers’ requirements.

- The carbon slag produced by the system can be controlled within 1~3%, and the proportion of carbon slag can be adjusted according to the demand.

- The system only needs one person on duty, or can provide 24-hour unattended service according to user needs, with low operating cost.

The System Has Longer Service Life And Easier Maintenance

- The service life of Haiqi biomass gasification system is about 15~20 years.

- The core components are made of stainless steel alloy material, and the system life is longer.

- Haiqi biomass gasification system has a simple structure and is easy to maintain.

- The whole system is clean and can realize with one-click cleaning and one-click start and stop directly without manual intervention.

Good economic benefits and superior environmental benefits play an important role in the development of green energy and energy conservation and emission reduction, and are the only way to promote green, circular and sustainable development.

Better environmental protection and energy-saving benefits; realize the efficient, pollution-free, and resource-based utilization of agricultural and forestry biomass, resulting in significant economic, social and ecological benefits.