- Home

- Companies

- Sitong Boiler

- Products

- Sitong - Model SZL - Biomass Pellet ...

Sitong - Model SZL -Biomass Pellet Water Tube Steam Boiler

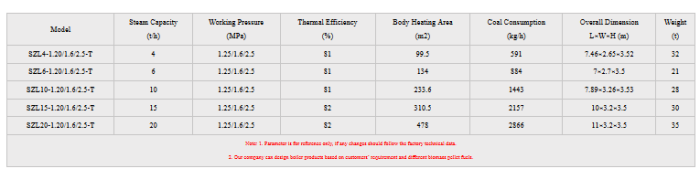

Biomass pellet fired water tube steam boiler is horizontal type double drums water tube boiler with high steam quality, the combustion equipment is chain grate. Sitong boiler takes several breakthroughs on boiler design, such as membrane water cooling wall, low thermal inertia design, and water cooling combustion chamber. This biomass pellet steam boiler adopts fast assembly or packaged assembly structure, boiler with steam capacity lower than 4t/h is fast assembly water tube structure, boiler with steam capacity between 6~25t/h is consisted of upper part (boiler heated part) and lower part (combustion equipment). This series boiler has reached the international advanced level on technology and performance, it has the advantages of compact structure, high steam quality, sufficient output, operate convenient and environmental protection.

- Steam Capacity 2t/h~30t/h

- Steam Pressure 0.7Mpa-3.8Mpa

- Fuel Biomass pellet, wood pellet, bagasse, rice husk, straw, coconut shell, cotton seeds, etc.

- Application wood processing, food & beverage, farm, textile plant, rice mill, paper processing, hospital, hotel, diaries, schools, etc.

- Certification ISO9001,CE,BV, SGS

- The small scale chain grate boiler could resist the temperature as high as 1200℃, long working life.

- The chain grate has a low biomass fuel leakage because of the small gap.

- Mechanized feed, high automatic degree, decrease labor cost.

- Convenient for maintenance, it could be done without boiler shut down.

- Based on customers’ requirement and fuel characteristics, the grate could be designed as reciprocal grate.