- Home

- Companies

- streisal GmbH

- Products

- Biosubstrator - Fermenter Agitator

Biosubstrator - Fermenter Agitator

High and adjustable stirring performance Great hydraulic thrust which can be adapted to the biological condition of the substrate / mixing task by means of a height adjustment. Unhindered substrate inflow. no shadowing effect from interfering fixtures. The large diamter of the propeller hub and -blade virtually eliminates the build-up of layers in this critical area.

- Propeller diameter 1.500 mm

- Required wall opening Chamber lining 600 x 600 mm or core hole 500 mm

- Required cover opening

- for lifting out the agitator shaft 1.500x1.20 mm

- Total weight approx. 900 – 1300 kg depending on the version

- Agitator shaft Solid, made of high-strength steel with acid-resistant polyolefin protective jacket

- Parts flushed with gas in the fermenter Stainless steel 1.4571 (V4A)

- Parts outside the fermenter Galvanised or painted/coated

- Propeller (Ø 1.500 mm) Stainless steel 1.4301 (V2A)

- ATEX-certified version for use in explosion protection zones 1 and 2

- Frequency inverter with parameterised safety software (torque limiting, etc.)

The agitators are available in various ignition protection types according to ATEX for use in explosion protection zones 1 or 2.

The large hydraulic thrust can be adapted to the biological condition of the substrate or the agitating task by means of height adjustment. The substrate can flow in without obstruction because the agitating elements are not covered by any obstructive built-in components. The large diameters of the propeller and hub prevent material wrapping itself around the blades, thus ensuring a constantly high efficiency is available.

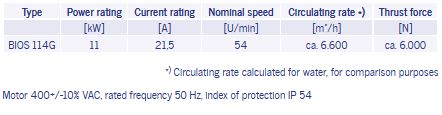

The high circulating rate and excellent efficiency of the Biosubstrator® result from the large propeller diameter and slow-running, frequency-controlled rotation speed.

Important wearing parts are mounted externally and are therefore easy to access for maintenance and servicing. For example, there is no need for the container roof (gas accumulator) to be opened regularly in biogas plants. The agitator shaft is sealed by a gas-tight siphon seal with contactless operation. In contrast to other rod agitators, there are no bearings or (mechanical) seals inside the tank!

The streisal Biosubstrator® is characterised by the sturdy configuration of the bearing bracket with regreaseable bearings and a large steel construction on the outside. Vibration dampers at the articulation points absorb peak vibrations and also contribute to the durability of the agitator.