- Home

- Companies

- Henan Gomine Machinery

- Products

- Gomine - Model GM-160/180/300 - ...

Gomine - Model GM-160/180/300 -Briquette Extruder Machine

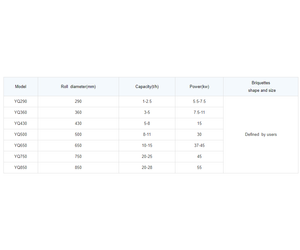

Briquette Extruder Machine can make coal or charcoal briquettes from coal or carbon powder. Different shape customization is accepted.

Briquette Extruder Machine is important forming equipment in the production process of charcoal making. The charcoal briquette can make full use of pulverized coal resources, reduce fuel costs, and increase the calorific value of coal, which has high economic benefits.

The charcoal extruder briquette machine mainly including a feeding port, a reducer, propel spirals, output shaft and a motor. The shaft seat and the machine body are rigidly connected with high concentricity. Each part has been debugged many times to help the whole machine run stably.

After the materials enter from the feeding port, they will be squeezed forward through the inner cone mold to make the compression between the materials is extremely tight. There is strong friction between the material and the cylinder, which causes the temperature of the coal powder to rise while generating heat, the moisture and the binder are more uniform, the plasticity of the coal is also greatly increased, and finally it is extruded in the flat part of the mold.

The charcoal briquette machine is important forming equipment in the production process of charcoal making.

Finally Briquettes: Briquette Extruder Machine can make coal or charcoal briquettes from coal or carbon powder. Different shape customization is accepted. The finished charcoal briquettes have high density, good strength, and are smokeless and tasteless during processing.

1.Automatic cutter. This kind of cutting knife is controlled by an infrared sensor probe, and the cutting length can be adjusted according to actual needs. The commonly used diameter is 10-12cm. The shortest diameter is 5cm.

Automatic cutter

Charcoal Briquette Cutting Device

2.Multifunctional charcoal cutter machine. This cutter adopts CNC numerical control system, and its length range is very wide, ranging from 3-40cm, the shortest can be 2.5cm. This cutter is not easily affected by the environment, strong light, and dust during the cutting process, and the finished product has a stable effect. Its small size saves space during transportation.

The material of the conveying wheel is stainless steel

Measure the distance by the number of turns of the wheel

Multifunctional charcoal cutter machine

3.Cubic charcoal briquettes cutting machine. The coal cut by this cutter is a square cube with an edge length of 2.5 cm. It is mainly composed of hob and baffle. The standard configuration is a 1.5-meter conveyor belt, and the length of the conveyor belt can be customized.

1.Add adhesive. Its function is to increase the viscosity between coal powder.

2.Change the physical state of pulverized coal, which is more conducive to the adhesion between the pulverized coal.

3.Control water content. The molding effect is different under different moisture content.

briquette machine, raymond mill, Biomass Briquette Machine, Carbonization Furnace, Pellet Machine